New Fodder Gives Bigger Fish

It’s cheaper, and it enables quicker growth and bigger fish. These are the key characteristics of a new fodder in fish farming, which will replace the traditional dry fodder. The raw material is simple: Fish waste.

Fish offal is a high-grade raw material with a low price. We want to use this to make the industry grow,” says Oistein Baekken, manager of GellyFeed Ltd.

We are acquiring capital and the industry is showing a great deal of interest in applying this future-oriented concept both to cod farming and salmon farming.

Contrary to the previously used dry fodder, GellyFeed allows more food substances in the fodder to remain in the body of the fish, instead of passing straight through it and into the water, where it may create environmental problems.

Tests show that the growth of salmon may be up to 15 percent higher with GellyFeed than with regular dry fodder. Using the new fodder, a fish farming plant that produces 675 tons of cut salmon will be able to produce an additional 100 tons of cut salmon a year,” Baekken says. When the fish grows faster, it will also get bigger during the same period, and this increases the marked price.

Flexibility is another advantage. Contrary to dry fodder, there is no need for additives like oil or starch in order to produce the fodder. Only maritime raw materials are needed. Fish offal from fat fish such as herring and mackerel are excellent salmon fodder, rich in energy. Offal from white fish such as haddock, saithe and cod offer protein-rich fodder for farmed cod.

GellyFeed is a result of ten years of research and development. It started with the RUBIN foundation, continued in Hydro and ended up in GellyFeed Ltd.

The development of GellyFeed has involved research and new knowledge in the chemical treatment of the pellet, in terms of nutrition and veterinary sanitation. The National Veterinary Institute has carried out several lab tests to verify that the processes will satisfy the EU requirements. With funds from the Research Council of Norway we have been able to carry out feeding experiments that demonstrate the excellent performance of the fodder, Baekken says. GellyFeed Ltd holds a patent in Norway and has applied for patent in 33 other countries.

Media Contact

More Information:

http://www.rcn.noAll latest news from the category: Agricultural and Forestry Science

Newest articles

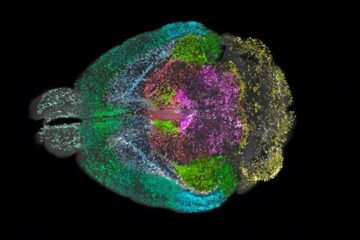

Advanced Brain Science Without Coding Expertise

Researchers at Helmholtz Munich and the LMU University Hospital Munich introduce DELiVR, offering a new AI-based approach to the complex task of brain cell mapping. The deep learning tool democratizes…

Transparent emissive microdisplays

… for ultra-light and compact augmented reality systems. As part of the HOT project (High-performance transparent and flexible microelectronics for photonic and optical applications), scientists from the Fraunhofer Institute for…

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…