Bringing precision farming to open field crops

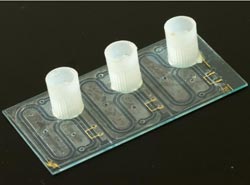

A unit of three chips for the measurement of NO3, NH4, K and PO4 (chip size 16 mm x 26 mm).<br>Foto: OPTIFERT Projekt <br>

How much water and fertilizer needs agricultural land for a successful harvest? Which nutrients are in the soil, which ones are lacking? ttz Bremerhaven and nine partners of the EU-funded project “OPTIFERT” present the development of a fully integrated on-demand fertigation system.

A soil nutrient sensor for the combined measurement of macronutrients at the field will correct the required crop growth model embedded in a fertigation software. The calculated fertilizer requirements will be delivered by a mixing and dosing unit specifically developed for open field crops.

In modern agriculture the amount of nutrients in soil is commonly adjusted by the application of fertilizers. The fertilizer dose has to be carefully adapted to the plant demands, since under-supply as well as over-supply lead to reduced yield. In addition, excessive use seriously harms the environment if fertilizers are not taken up by crops but get washed into ground water. In order to apply the appropriate amount of fertilizers, precise knowledge of nutrient concentrations in the soil and plant needs is required.

At the moment open field crops are fertilized using slow-dissolving solid fertilizer, applied while sowing in an experience-based quantity. Once the fertilizer is applied, the farmer has no control on the rate in which it is dissolved and so when it is available for the plants, or has the possibility of correcting the dose during the growth of the crop.

A system for calculating and applying on-demand fertilizers in open field crops, together with a fast and simple method for the routine surveillance of these nutrients is not yet available. “A system like this can also help us farmers to save time. We can control it with the computer in our office, and that way we have more time to do other things equally important.” Frank Hausmann, Farm Manager at the OPTIFERT test site.

Fertigation system comes with three modules

The full fertigation system contains three modules: composed of first: A soil nutrient sensor system for the combined measurement of NO3, NH4, K and PO4 at the field. For the measurement, a soil sample is suspended in a universal extraction liquid. After filtration, the amount of dissolved nutrients is measured in this liquid. In this way, only a single extraction procedure followed by a single measurement is required, minimizing the work for the generation of nutrient concentration maps and depth profiles.

Second: A software system which will receive the sensor data and process it together with crop growth models and weather data to calculate the required amount of fertilizers for each growth stage.

Third: A mixing and dosing unit, designed specifically for the requirements of an open field, and prepared to dissolve any needed fertilizer combination. The dosing unit can be coupled with any standard irrigation system, adapting the dose not only to the required amount of nutrients for each crop period but also to dynamically adapt to the variation of irrigation rate.

Project results

The three developed prototypes have been tested in a corn field in Brandenburg, Germany, during the season 2013. 25 Ha test site in this field has been fertigated using the OPTIFERT prototypes. The soil and plants have been monitored and analysed periodically during the whole season, as well as neighbour 25Ha reference test, which was fertilized under standard practice. Biomass samples taken at the end of August show 9% yield increase on the OPTIFERT test site. The performance of prototypes and test field have proven satisfactory.

The following partners are involved in the OPTIFERT project. Research partners: Vienna University of Technology (Austria), University of Bremen (Germany), University of Warmia and Mazury (Olsztyn, Poland), ttz Bremerhaven (Germany). Industrial partners: Pessl Instruments GmbH (Austria), Integrated Microsystems Austria GmbH (Austria), Soil Moisture Sense LTD (Great Britain), Hydro-Air GmbH (Germany), Agrargesellschaft “Niederer Fläming” mbH Petkus (Germany).

Movie about the project on euronews/futuris: Intelligent irrigation: growing green http://www.ttz-bremerhaven.de/en/research/environment/research-projects/1120-optifert.html

ttz Bremerhaven is an innovative provider of research services and operates in the field of application-oriented research and development. Under the umbrella of ttz Bremerhaven, an international team of experts is working in the areas of food, environment and health.

Media Contact:

Christian Colmer

Head of Communications

ttz Bremerhaven

Fischkai 1

D-27572 Bremerhaven (Germany)

Tel.: +49 (0)471 80934 903

Fax: +49 (0)471 4832 129

ccolmer@ttz-bremerhaven.de

www.ttz-bremerhaven.de

www.facebook.com/ttzBremerhaven

www.twitter.com/ttzBremerhaven

www.xing.com/companies/ttzbremerhaven

Media Contact

All latest news from the category: Agricultural and Forestry Science

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…