Super-Stretchable Yarn Is Made of Graphene

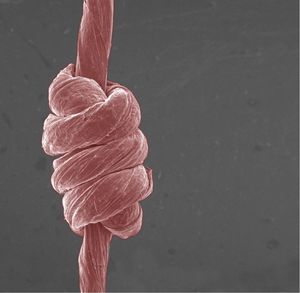

Terrones Group/Penn State Strong, stretchable fibers made of graphene oxide can be knotted like yarn.

The researchers made a thin film of graphene oxide by chemically exfoliating graphite into graphene flakes, which were then mixed with water and concentrated by centrifugation into a thick slurry. The slurry was then spread by bar coating – something like a squeegee – across a large plate.

When the slurry dries, it becomes a large-area transparent film that can be carefully lifted off without tearing. The film is then cut into narrow strips and wound on itself with an automatic fiber scroller, resulting in a fiber that can be knotted and stretched without fracturing.

“We found this graphene oxide fiber was very strong, much better than other carbon fibers. We believe that pockets of air inside the fiber keep it from being brittle,” says Mauricio Terrones, professor of physics, chemistry and materials science and engineering at Penn State.

Terrones and colleagues believe this method opens up multiple possibilities for useful products. For instance, removing oxygen from the GO fiber results in a graphene fiber with high electrical conductivity.

Adding silver nanorods to the graphene film would increase the conductivity to the same as copper, which could make it a much lighter weight replacement for copper transmission lines. Many kinds of highly sensitive sensors are imaginable.

“The importance is that we can do almost any material, and that could open up many avenues – it’s a lightweight material with multifunctional properties,” Terrones remarks.

And the main ingredient, graphite, is mined and sold by the ton.

Their discovery was reported online in a recent issue of ACS Nano and titled “Super-stretchable Graphene Oxide Macroscopic Fibers with Outstanding Knotability Fabricated by Dry Film Scrolling.” (ACS Nano 2014, DOI: 10.1021/nn501098d) Penn State and Shinshu University have applied for a joint patent on the process.

The researchers received support from the Research Center for Exotic Nanocarbons, Japan, and the Center for Nanoscale Science, Penn State. Contact Mauricio Terrones at mutt11@psu.edu.

Media Contact

More Information:

http://www.psu.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…