"Spacetex" project takes functional textiles into outer space

The International Space Station ISS orbits the Earth at a height of 400 kilometres and a speed of 28,000 km/hr. ©NASA

Experiments in zero gravity help with the development of innovative textiles for extreme conditions on Earth

The “Spacetex” project and its aims

– Germany)Germany) are expecting unique results from the joint undertaking. It is hoped that the tests deliver essential information for developing new textile products for use in extreme climatic and physiological conditions on Earth.

Equally as important, the data obtained should help optimise astronauts' clothing for future space voyages and long-term missions such as the approximately three-year voyage to Mars that is planned for 2030.

The challenges of zero gravity

Project leader Dr. Jan Beringer of the Hohenstein Institute sees great potential for improving the comfort and other performance features of garments in space: “Among other things, the lack of gravity affects the way body heat and sweat are transported through clothing that is worn next to the skin. To ensure that the body's cooling mechanism is still properly maintained, textiles have to be specially adapted for use in space.” Industrial researcher Dr. Beringer, who is listed as the project’s Principal Investigator (PI), believes performance-based textile functions will be key in future developments. These include, for example, antimicrobial textile finishes to minimise the odour formation that occurs as sweat is broken down by bacteria.

Wearing tests by astronaut Dr. Alexander Gerst

At the end of February, Dr. Jan Beringer and Prof. Dr. Hanns-Christian Gunga of the Center of Space Medicine at the Charité in Berlin, who is also Principal Investigator (PI) in the project, attended Dr. Alexander Gerst's training for the project at the European Astronaut Centre (EAC) in Cologne. In preparation for his duties while in orbit, Dr.Gerst performed four intensive treadmill workouts on four separate days during his preflight training. During two of the training sessions, he wore functional underwear made

of special polyester. Dr. Gerst wore a conventional cotton set of underwear, consisting of a T-shirt and shorts, for the remaining two sessions. Using a questionnaire, the 37- year-old from Künzelsau assessed how well body heat and sweat were wicked away from his body by the clothing systems. Dr. Alexander Gerst will also give his subjective impressions immediately after the training sessions in space; this will provide the first important comparative data for the “Spacetex” project.

Space-proven for extreme situations on Earth

It is expected that the data from the Dr. Gerst experiments will aid in Prof. Dr. Hanns-Christian Gunga’s reserach. For years, Gunga has been studying the effects that weightlessness in space, or in extreme climatic conditions on Earth, has on the human body. “In zero gravity, the breakdown of muscle and bone tissue begins very quickly. To counteract that degeneration, working on special training equipment is extremely important for astronauts. During that process, the body gives off heat just as it does on Earth, and tries to cool itself down by releasing and evaporating sweat. However, due to the lack of gravity and therefore of a flow of heat (convection), neither the body heat nor the sweat are transported away onto clothing or into the environment as they are on Earth.” Instead, the heat envelops the body almost like an aura. Especially if clothing is loose-fitting, sweat remains stubbornly on the skin. This means the cooling effect on the body is lost and the training imparts greater physiological strain than it does on Earth, even for very fit astronauts.

In addition to their potential use in space, space-proven textiles are also of great interest when developing textiles for extreme conditions here on Earth. For Hans-Jürgen Hübner, Schoeller Textil AG, this is an important reason why the textile manufacturer is involved in this industry-funded research project: “We will feed the findings from the “Spacetex” project into our product development and optimisation work. Future astronauts will benefit from this work. We’ll also make sure that people here on Earth who push the limits of their physical endurance or have to deliver peak performance in extreme conditions benefit as well. That includes, of course, athletes of all kinds but also firefighters, catastrophe relief workers and members of the armed forces.”

Experiments using the Hohenstein skin model

Alongside the subjective wear tests, objective evaluations of moisture and heat management are another vital data source for PI Dr. Beringer. The functional and cotton textiles were subjected to an extensive series of tests on the Hohenstein skin model that simulates the thermoregulatory system of human skin. Various clothing physiology parameters such as water vapour resistance, which indicates breathability, and thermal insulation were measured in standardised climatic conditions and normal gravity. Because of the great weight of the measuring equipment, it is impossible to bring it on board the ISS.

In order to be able to take comparative measurements in micro-gravity, the Hohenstein Institute is developing a special version of the Hohenstein skin model that could possibly be expected to be used in 2016 on board an Airbus A300 during the parabolic flights. During these flights, the aircraft climbs steeply out of horizontal flight, reduces the thrust of the turbines and flies a parabola (ellipse) during which weightlessness is experienced for about 22 seconds. Altogether, such a flight offers about 35 minutes of weightlessness – alternating with normal and twice the normal gravitational force – for researchers to use during experiments.

Odour analysis and microbiological tests

After the astronaut testing in Cologne, the test textiles were packed in airtight containers and later tested at the Hohenstein Institute for odour formation and number of residual bacteria. So that similar tests can be carried out on the textiles after the training sessions in space, Dr. Alexander Gerst will return with them, again in air-tight packaging, in November 2014.

Little Tenax tubes will serve as the “odour trap”. Special polymers will absorb and preserve the odour molecules so that they can be counted after the mission using the GC/MS (gas chromatography mass spectrometer). In microbiological tests, the Hohenstein scientists will again count the number of bacteria adhering to the textile and compare the figures. As with the wearing comfort tests, the findings for functional and cotton textiles in normal and micro-gravity will be compared.

Always up-to-date

The project partners provide regular updates on various milestones during the “Spacetex” project. As of 1 April 2014 interim results and more information are provided on a special website www.spacetex-project.de. Further information can be found at the following links for “Blue Dot” mission and astronaut Dr. Alexander Gerst.

Additional information:

“Blue Dot” mission

Biography of Dr. Alexander Gerst

Contact:

Hohenstein Institute

Dr. Jan Beringer

j.beringer@hohenstein.de

www.hohenstein.com

Schoeller Textil AG

Dagmar Signer

dagmar_signer@schoeller-textiles.com

www.schoeller-textiles.com

http://www.hohenstein.com

http://www.schoeller-textiles.com

http://www.spacetex-project.de

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

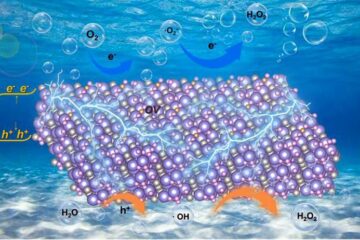

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….

Uranium-immobilizing bacteria in clay rock

Microbial reduction reduces mobility of uranium compounds. When designing repositories for high-level radioactive waste in deep geological layers, various factors must be carefully considered to ensure their long-term safety. Among…