Singapore-made anti-reflective plastics to be commercialised

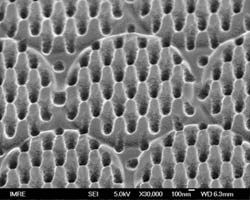

Scanning electron microscope (SEM) image showing the engineered anti-reflective nanostructures that mimic structures found in a moth’s eye.<br>Copyright : IMRE<br>

Researchers from A*STAR’s Institute of Materials Research and Engineering (IMRE) and their commercial partners have developed a new plastic that reflects just 0.09 – 0.2% of the visible light hitting its surface. This matches or betters existing anti-reflective and anti-glare plastics in the market, which typically have reported reflectivity of around 1% of visible light.

Such plastics are used in anything from TV displays to windows and even solar cells. Because of the unique nanotechnology method used, the new plastic developed by IMRE maintains very low reflectivity (

“The new plastic was made possible because of the unique nanoimprint expertise that we have developed at IMRE,” said Dr Low Hong Yee, the senior scientist who is leading the research. Several companies are in the process of licensing the anti-reflective nanostructure technology from Exploit Technologies Pte Ltd, the technology transfer arm of A*STAR. “We are also developing complementary research that allows the technology to be easily ramped-up to an industrial scale,” explained Dr Low.

This plastic material is the first successful result of the IMRE-led Industrial Consortium On Nanoimprint (ICON), which partners local and overseas companies to promote the manufacturing of nanoimprint technology. Nanoimprinting relies on engineering the physical aspects of the plastics rather than using harmful chemicals to change the properties of the plastic. The technology has allowed the researchers to create very unique, complex hierarchical ‘moth eye-like’ anti-reflective structures where nanometer-sized structures are placed on top of other microstructures – different from how other similar plastics are made. This formed special patterns that are better at reducing glare and reflection and provides wider viewing angles than the current available plastics.

“This is an exciting innovation – mimicking nature through the nanoimprint technology to solve real world problems. I am very pleased that the collaboration with industry has helped move this R&D from the laboratory to application in the industry, said Prof Andy Hor, IMRE’s Executive Director. He adds, “The development of the new plastic is a testament to the strength of Singapore’s advanced R&D capabilities, the benefits of nanoimprint technology and the confidence that companies place on our technologies.”

“The outstanding results from this consortium work will benefit our company's expansion into new markets such as in the touchscreen panel and solar business sectors,” said Mr Wilson Kim Woo Yong, Director, Global Marketing from Young Chang Chemical Co., Ltd.

“We have been very impressed with the developed technology and with the excellent team of researchers working on the anti-reflective structures”, said Mr Tatsuo Shirahama, President from Innox Co. Ltd.

“The results from the consortium work are key in the decision making for our future strategic planning,” said Dr Yuji Akatsu, Business Unit Manager from the Nanotechnology business unit, Advanced Products Business Headquarters, NTT-AT.

Annex A: A*STAR Corporate Profiles

Annex B: More information on ICON, nanoimprint technology and anti-reflective surfaces

For media enquiries, please contact:

Mr Eugene Low

Manager, Corporate Communications

for Institute of Materials Research and Engineering (IMRE)

3, Research Link

Singapore 117602

DID +65 6874 8491

Mobile +65 9230 9235

Email loweom@scei.a-star.edu.sg

For technical enquiries, please contact:

Dr Jaslyn Law

Scientist II

Institute of Materials Research and Engineering (IMRE)

3, Research Link

Singapore 117602

DID +65 6874 7902

E-mail lawj@imre.a-star.edu.sg

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…