Silicone liquid crystal stiffens with repeated compression

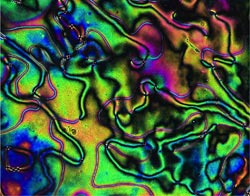

A liquid crystal sample like this one, seen under a microscope, gets tougher when repeatedly compressed, according to research at Rice University. (Credit: Verduzco Laboratory/Rice University)<br>

Squeeze a piece of silicone and it quickly returns to its original shape, as squishy as ever. But scientists at Rice University have discovered that the liquid crystal phase of silicone becomes 90 percent stiffer when silicone is gently and repeatedly compressed. Their research could lead to new strategies for self-healing materials or biocompatible materials that mimic human tissues.

A paper on the research appeared this month in Nature’s online journal Nature Communications.

Silicone in its liquid crystal phase is somewhere between a solid and liquid state, which makes it very handy for many things. So Rice polymer scientist Rafael Verduzco was intrigued to see a material he thought he knew well perform in a way he didn’t expect. “I was really surprised to find out, when my student did these measurements, that it became stiffer,” he said. “In fact, I didn’t believe him at first.”

The researchers had intended to quantify results seen a few years ago by former Rice graduate student Brent Carey, who subjected a nanotube-infused polymer to a process called repetitive dynamic compression. An astounding 3.5 million compressions (five per second) over a week toughened the material, just like muscles after a workout, by 12 percent. What Verduzco and lead author/Rice graduate student Aditya Agrawal came across was a material that shows an even stronger effect. They had originally planned to study liquid crystal silicone/nanotube composites similar to what Carey tested, but decided to look at liquid crystal silicones without the nanotubes first. “It’s always better to start simple,” Verduzco said.

Silicones are made of long, flexible chains that are entangled and knotted together like a bowl of spaghetti. In conventional silicones the chains are randomly oriented, but the group studied a special type of silicone known as a liquid crystal elastomer. In these materials, the chains organize themselves into rod-shaped coils. When the material was compressed statically, like squeezing a piece of Jell-O or stretching a rubber band, it snapped right back into its original shape. The entanglements and knots between chains prevent it from changing shape. But when dynamically compressed for 16 hours, the silicone held its new shape for weeks and, surprisingly, was much stiffer than the original material.

“The molecules in a liquid crystal elastomer are like rods that want to point in a particular direction,” Verduzco said. “In the starting sample, the rods are randomly oriented, but when the material is deformed, they rotate and eventually end up pointing in the same direction. This is what gives rise to the stiffening. It’s surprising that by a relatively gentle but repetitive compression, you can work out all the entanglements and knots to end up with a sample where all the polymer rods are aligned.”

Before testing, the researchers chemically attached liquid crystal molecules – similar to those used in LCD displays — to the silicones. While they couldn’t see the rods, X-ray diffraction images showed that the side groups – and thus the rods – had aligned under compression. “They’re always coupled. If the side group orients in one direction, the polymer chain wants to follow it. Or vice versa,” Verduzco said.

The X-rays also showed that samples heated to 70 degrees Celsius slipped out of the liquid crystal phase and did not stiffen, Verduzco said. The stiffening effect is reversible, he said, as heating and cooling a stiffened sample will allow it to relax back into its original state within hours.

Verduzco plans to compress silicones in another phase, called smectic, in which the polymer rods align in layers. “People have been wanting to use these in displays, but they’re very hard to align. A repetitive compression may be a simple way to get around this challenge,” he said.

Since silicones are biocompatible, they can also be used for tissue engineering. Soft tissues in the body like cartilage need to maintain strength under repeated compression and deformation, and liquid crystal elastomers exhibit similar durability, he said.

The paper’s co-authors include Carey, a Rice alumnus and now a scientist at Owens Corning; graduate student Alin Chipara; Yousif Shamoo, a professor of biochemistry and cell biology; Pulickel Ajayan, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of mechanical engineering and materials science, chemistry and chemical and biomolecular engineering; and Walter Chapman, the William W. Akers Professor of Chemical and Biomolecular Engineering, all of Rice; and Prabir Patra, an assistant professor of mechanical engineering at the University of Bridgeport with a research appointment at Rice. Verduzco is an assistant professor of chemical and biomolecular engineering.

The research was supported by an IBB Hamill Innovations Grant, the Robert A. Welch Foundation, the National Science Foundation and the National Institutes of Health, through the National Institute of Allergy and Infectious Diseases.

Read the abstract at http://www.nature.com/ncomms/journal/v4/n4/full/ncomms2772.html.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related Materials:

Verduzco Laboratory: http://verduzcolab.blogs.rice.edu

Media Contact

More Information:

http://www.rice.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…