New sensor construction

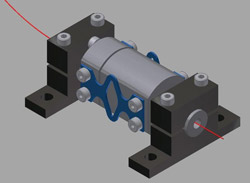

The prototype<br>photo: ifw jena<br>

A special sensor construction for strain measurement was developed in a research project at Günter-Köhler-Institut für Fügetechnik und Werkstoffprüfung GmbH (ifw) in Jena. This construction allows a multiple use of the fiber bragg grating sensors (FBGS), which are fixed in a way that the sensor housing does not disturb their high sensitivity.

FBGS are sensors where a UV-Laser has inscribed a grating (interference filter) in a section of the glass fiber. If the fiber gets minimally stretched or compressed (1 pm/1 µε), the reflected wavelength inside the fiber changes because the grating spaces get bigger or smaller. This effect can also be caused by temperature differences. These small strain changes can be detected and analyzed with special opto-electric devices (interrogators). The advantage of this technology is that parameters like strain or temperature are measured and transmitted in a non-electrical way. This makes these sensors suitable for an application in electro-magnetic fields, on high voltage power lines or in explosion-protected zones. An easy handling and the reusability of fiber bragg grating sensors are essential for a further distribution and cost reduction of this still rather expensive technology.

Usually FBGS are glued on the object which makes a reuse of the fiber impossible, because the fiber will get destroyed during the dismounting. That is why the sensor is considered a “lost sensor” after the measurement tasks. There are also holding constructions for the sensors which can be non-destructively dismounted and which keep the initial tension. But the disadvantage of such constructions is the mechanical damping which lowers the sensitivity and the ability to transmit high frequencies.

The new sensor construction combines the advantages of the fiber bragg grating technology with an easy mounting without losing the high frequency sensitivity. Therefore the sensor construction is divided into two parts, each like a fixed bearing. The only connection between these two parts is the sensitive part of the fiber itself, which prevents the damping. For the dismounting, however, it is necessary to keep the initial tension. This is realized through a transport lock which is applied before dismounting. It also protects the fiber against overload.

In co-operation with the University of Applied Sciences Jena the functionality was proved by means of a prototype which was tested on a spot welding gun measuring force. The detailed resolution of the spot welding process is important. The holding force and also very small force differences during the current time are measurable. Weld spatter and even the development of the nugget diameter are visible, which makes the sensor suitable for a later use in welding quality control systems. The aim of manufacturing industry still is to have a 100% non-destructive quality control of spot welds. This new sensor construction has the potential to make the production of e.g. car bodies safer and more efficient.

This project was sponsored via EuroNorm Gesellschaft für Qualitätssicherung und Innovationsmanagement mbH by Federal Ministry of Economics and Technology within the promotional program “Promotion of initial industrial research in disadvantaged regions” (support code: VF081021).

Dr.-Ing. H. Müller, Dipl.-Ing. (FH) J. Kammann und Dipl.-Ing. (FH) S. Lorenz

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…