Self-adaptive material heals itself, stays tough

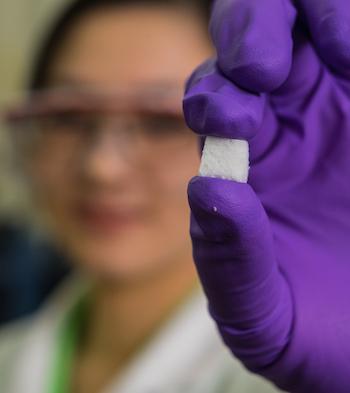

Rice University postdoctoral researcher Pei Dong holds a sample of SAC, a new form of self-adapting composite. The material has the ability to heal itself and to regain its original shape after extraordinary compression. Credit: Jeff Fitlow/Rice University

An adaptive material invented at Rice University combines self-healing and reversible self-stiffening properties.

The Rice material called SAC (for self-adaptive composite) consists of what amounts to sticky, micron-scale rubber balls that form a solid matrix. The researchers made SAC by mixing two polymers and a solvent that evaporates when heated, leaving a porous mass of gooey spheres. When cracked, the matrix quickly heals, over and over. And like a sponge, it returns to its original form after compression.

The labs of Rice materials scientists Pulickel Ajayan and Jun Lou led the study that appears in the American Chemical Society journal ACS Applied Materials and Interfaces. They suggested SAC may be a useful biocompatible material for tissue engineering or a lightweight, defect-tolerant structural component.

Other “self-healing” materials encapsulate liquid in solid shells that leak their healing contents when cracked. “Those are very cool, but we wanted to introduce more flexibility,” said Pei Dong, a postdoctoral researcher who co-led the study with Rice graduate student Alin Cristian Chipara. “We wanted a biomimetic material that could change itself, or its inner structure, to adapt to external stimulation and thought introducing more liquid would be a way. But we wanted the liquid to be stable instead of flowing everywhere.”

In SAC, tiny spheres of polyvinylidene fluoride (PVDF) encapsulate much of the liquid. The viscous polydimethylsiloxane (PDMS) further coats the entire surface. The spheres are extremely resilient, Lou said, as their thin shells deform easily. Their liquid contents enhance their viscoelasticity, a measure of their ability to absorb the strain and return to their original state, while the coatings keep the spheres together. The spheres also have the freedom to slide past each other when compressed, but remain attached.

“The sample doesn't give you the impression that it contains any liquid,” Lou said. “That's very different from a gel. This is not really squishy; it's more like a sugar cube that you can compress quite a lot. The nice thing is that it recovers.”

Ajayan said making SAC is simple, and the process can be tuned — a little more liquid or a little more solid — to regulate the product's mechanical behavior.

“Gels have lots of liquid encapsulated in solids, but they're too much on the very soft side,” he said. “We wanted something that was mechanically robust as well. What we ended up with is probably an extreme gel in which the liquid phase is only 50 percent or so.”

The polymer components begin as powder and viscous liquid, said Dong. With the addition of a solvent and controlled heating, the PDMS stabilizes into solid spheres that provide the reconfigurable internal structure. In tests, Rice scientists found a maximum of 683 percent increase in the material's storage modulus – a size-independent parameter used to characterize self-stiffening behavior. This is much larger than that reported for solid composites and other materials, they said.

Dong said sample sizes of the putty-like material are limited only by the container they're made in. “Right now, we're making it in a 150-milliliter beaker, but it can be scaled up. We have a design for that.”

###

Co-authors are Rice postdoctoral researchers Bo Li, Yingchao Yang, Hua Guo, Liehui Ge and Liang Hong; graduate student Sidong Lei; undergraduate students Bilan Yang and Qizhong Wang; alumnus Phillip Loya; Emilie Ringe, an assistant professor of materials science and nanoengineering and of chemistry; Robert Vajtai, a senior faculty fellow in materials science and nanoengineering, and Ming Tang, an assistant professor of materials science and nanoengineering; Mircea Chipara, an assistant professor of physics and geology at the University of Texas-Pan American, and postdoctoral researchers Gustavo Brunetto and Leonardo Machado and Douglas Galvao, a professor at the State University of Campinas, Brazil.

Ajayan is chair of Rice's Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry. Lou is a professor of materials science and nanoengineering and of chemistry and associate chair of the Department of Materials Science and NanoEngineering.

The Air Force Office of Scientific Research and the Department of Defense supported the research.

Read the abstract at http://pubs.

This news release can be found online at http://news.

Follow Rice News and Media Relations via Twitter @RiceUNews

Video: https:/

Related Materials:

Ajayan Research Group: http://ajayan.

Lou Research Group: http://n3lab.

Rice Department of Materials Science and NanoEngineering: https:/

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,888 undergraduates and 2,610 graduate students, Rice's undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for best quality of life and for lots of race/class interaction by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…