Study sets benchmark properties for popular conducting plastic

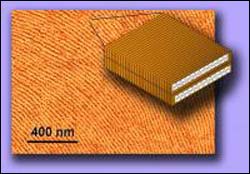

Atomic force microscopy image of aligned nanofibrils of a highly conducting plastic. Each nanofibril is made of stacks of regioregular polythiophene (RRP) molecules. Charge carriers move particularly well along the...

Results essential to optimize materials for diverse applications

Steadily increasing the length of a purified conducting polymer vastly improves its ability to conduct electricity, report researchers at Carnegie Mellon University, whose work appeared March 22 in the Journal of the American Chemical Society. Their study of regioregular polythiophenes (RRPs) establishes benchmark properties for these materials that suggest how to optimize their use for a new generation of diverse materials, including solar panels, transistors in radio frequency identification tags, and light-weight, flexible, organic light-emitting displays.

“We found that by growing very pure, single RRP chains made of uniform small units, we dramatically increased the ability of these polymers to conduct electricity,” said Richard D. McCullough, who initially discovered RRPs in 1992. “This work establishes basic properties that researchers everywhere need to know to create new, better conducting plastics. In fact, designing materials based on these results could completely revolutionize the printable electronics industry.”

“Our results are very significant, since they cast new light on the mechanism by which polymers conduct electricity,” said Tomasz Kowalewski, associate professor of chemistry and senior author on the study.

Unlike plastics that insulate, or prevent, the flow of electrical charges, conducting plastics actually facilitate current through their nanostructure. Conducting plastics are the subject of intense research, given that they could offer light-weight, flexible, energy-saving alternatives for materials used in solar panels and screen displays. And because they can be dissolved in solution, affixed to a variety of templates like silicon and manufactured on an industrial scale, RRPs are considered among the most promising conducting plastics in nanotech research today, according to McCullough, dean of the Mellon College of Science and professor of chemistry.

“Our tests showed that highly uniform RRPs self-assemble into well-defined elongated aggregates called nanofibrils, which stack one against the other,” Kowalewski said. “About 5,000 of these nanofibrils would fit side by side in the width of a human hair. The presence of these well-defined structures allowed us for the first time to make a connection between the size of polymer molecules, the type of structure they form and the ease with which current can move through nanofibril aggregates.” (See image.)

The vast improvement in conductivity is tied to several key properties that were unambiguously shown for the first time in this study, according to Kowalewski.

“We made the key discovery that mobility — how easily electrons move — increases exponentially as the width of a nanofibril increases,” Kowalewski said. Each rope-like nanofibril actually is a stack of RRP molecules, so the longer these molecules, the wider the nanofibril and the faster the electrical conductivity. (See image insert of RRP stacks.) In this way, electricity moves preferably perpendicular through the rows of naturally aligned nanofibrils.

“We found that charge carriers encounter fewer hurdles when jumping between wider nanofibrils,” said Kowalewski. “Ultimately through this study, we found that the nanostructure of our conducting plastic profoundly enhances its ability to conduct electricity.”

Conductivity increases with the length of an RRP molecule — and hence the width of each nanofibril — because it takes less time for a charge carrier to cross through wider nanofibrils than narrower ones. (Charge carriers are unbound particles that carry an electric charge through a molecular structure). All this can be tied to the fact that a charge carrier that enters a short molecule disrupts its energetic environment considerably more than if that same charge carrier enters a long molecule. This energetic hurdle, called reorganization energy, thus slows the movement of charge carriers that move from short molecule to short molecule. The energetic hurdle is lower for a long molecule, which can absorb changes to its electrical environment more easily. This phenomenon could be one of the reasons why charge carriers jump more quickly from long molecule to long molecule, according to Kowalewski.

“We hope that these findings will stimulate further theoretical and experimental work which will significantly improve the performance of polymer-based electronics and open the way to a wide range of applications,” Kowalewski said.

To show that increasing the width of RRP nanofibrils exponentially increased charge carrier mobility, the Carnegie Mellon team first created pure RRPs of uniform size, or molecular weight. Next, they placed the drops of RRPs dissolved in a solvent onto silicon chips whose surfaces were specially prepared for use as nanotransistors. Such “drop casting” allowed the team to create a series of nanostructures that varied in accordance with the length of the RRP chains initially present in solution.

The team ran a current through these different RRP-based nanotransistors to measure their ability to conduct electricity. They used atomic force microscopy and a technique called grazing-incidence small-angle X-ray scattering to verify that periodic, stacked structure of different RRPs indeed formed nanofibrils of corresponding widths. The latter technique was performed using the High Energy Synchrotron Source at Cornell University.

The team of investigators included students Rui Zhang in the Department of Chemistry; Bo Li in the laboratory of David Lambeth, professor of electrical and computer engineering; and faculty from the Department of Physics, who participated in X-ray scattering studies.

Media Contact

More Information:

http://www.cmu.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…