Innovation in Nanoporous Chemistry

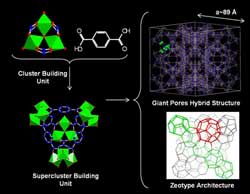

Starting from simple assemblies and linking units, larger and larger building blocks combine to form crystalline nanoporous materials with more surface area than zeolites. The Zeotype architecture of MIL-101 displays mesoporous cages with diameters of 29 Å (green) and 34 Å (red), featuring 12 Å pentagonal and 15 Å hexagonal openings. Credits: Science

Science researchers from the University of Versailles (France), in collaboration with the ID31 beam line at the European Synchrotron Radiation Facility (ESRF), report their progress in the design and characterisation of microporous materials. The combination of adept chemistry and computational design made possible the synthesis of a new material, named MIL-101 by its originators, (where MIL stands for Matériaux de l’Institut Lavoisier), with very large internal pores (ø~3.4nm) and surface area (5,900 m2.g-1). The new, crystalline material is representative of a class of compounds, known as metal organic framework materials, (MOFs), with potential applications in many fields including chemical separation, heterogeneous catalysis and gas storage. Confirmation of the structure of the new material exploited the intense X-ray beams at the ESRF.

Porous materials with large, regular, accessible cages and tunnels are increasingly in demand for many applications including chemical separation or purification, catalysis, molecular sensors, electronics and gas storage. Depending on their structure and pore size, these materials allow molecules of only certain shapes and sizes to enter the pores, a property known as shape selectivity. The environment within the pores can be very different to that outside, thus promoting chemical reactions that do not occur in the bulk material. Another prospective use is as templates for forming calibrated, monodisperse nanomaterials. In this respect, the larger the pores, the wider the range of reactants that can be manipulated or stored.

Férey and co-workers’ strategy combined three main ideas. First, discrete multi-atom building units were designed and generated in solution (Fig. 1). Second, with the aim of producing a compound with large pores, the building units were combined to produce larger units. For MIL-101 the key building unit is a supercluster of four smaller clusters linked by difunctional organic components to make a large tetrahedral assembly. The third idea involves being sure of what you’ve actually made, i.e. how to determine the structure of the new material. It is well known that it becomes increasingly difficult to grow highly diffracting single crystals as structures grow larger. When single crystals are unavailable, powder diffraction can provide sufficient information for structure solution. Based on their understanding of the ways the building units might combine, possible structural models were predicted and assessed via a computational strategy that calculated their relative stability. Favourable solutions were then compared with the high quality powder diffraction data collected from MIL-101 at ESRF. Once a good match between the predicted and measured powder patterns was seen, the researchers could be sure of the nature of their new material.

This breakthrough opens up a new field for targeted chemistry, computational methods for structure prediction and most importantly novel materials with useful applications. Férey and co-workers describe the hydrid solid, MIL-101, as an excellent candidate for the storage of gas, creation of nano-objects in a regular and monodisperse mode with specific physical properties, or for drug delivery. Recent studies on smaller porous materials carried out by various research groups around the world leave open the possibility of successfully creating hydrid materials with even larger pores and more complex structures keeping always in mind that the most important goal should be to incorporate useful functions.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…