Computer program reveals optimum microstructure for new materials

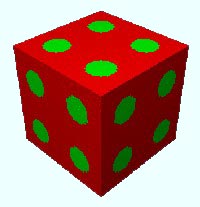

These images show shapes that a computer program found as the optimum structure for a composite material that conducts both heat and electricity. <br>

Technique could help bring efficiency of biology to man-made materials

A Princeton chemist has developed a general mathematical system for designing materials that perform two functions at once, even when the desired properties sometimes conflict with each other.

Salvatore Torquato and colleagues used computers to calculate the optimum structure for any material that is a composite of two substances with differing properties. The achievement is the first simple example of a mathematically rigorous method for optimizing the design of multifunctional composites, which are an increasingly common kind of material.

The approach could help bring to man-made materials the efficiency of design that characterizes so many biological materials. “Biological materials are inherently multifunctional,” said Torquato. “They have evolved over millions of years to cope with a wide range of situations, so they perform a variety of functions well.”

A tree, for example, has to support its weight and resist winds while transporting liquids up and down its length, said Torquato, who is a professor in the Princeton Materials Institute as well as the Department of Chemistry. “Until our work, however, there has been no clear and simple example that rigorously demonstrates the effect of competing property demands on composite microstructures.”

In addition to its possible applications in materials science, the method may help biologists study natural materials, such as the walls of a cell, to understand why they are built as they are. “Using rigorous optimization techniques, we are now in a position to test some of the basic tenets of biology,” Torquato said. “Are there elements of biology — perhaps subsystems within an organism or cell — that are optimized in any sense?”

Torquato and co-authors Sangil Hyun, a postdoctoral fellow, and Aleksandar Donev, a graduate student, described their findings in a paper published in the Dec. 23 edition of Physical Review Letters.

In their paper, the scientists demonstrated their approach by finding the ideal structure for a composite that is good at conducting both electricity and heat. Many materials already are good at both those tasks, but Torquato chose ones that are good at only one or the other. Running the scientists’ program, the computer arrived at surprisingly complex shapes as the optimum way in which the two materials should mix with each other at a microscopic scale.

The technique is general and could be used to optimize many properties, Torquato said. The technology already exists to make materials assemble themselves into finely tuned micro-scale patterns like the ones the scientists generated in their demonstration, Torquato said.

“I think it’s phenomenal work and it’s something that is very needed and timely,” said Jeff Brinker, a senior scientist at Sandia National Laboratory and professor of chemical and nuclear engineering at the University of New Mexico. Brinker is preparing to collaborate with Torquato to test the idea in actual materials.

As fabrication techniques improve, materials scientists increasingly need such theoretical work to guide them, Brinker said. “How should we direct the self assembly? Sometimes it’s not very intuitive what the optimum structure should be.”

The shapes produced by the computer are interesting in themselves, said Torquato. The best structure for simultaneous heat and electricity flow turned out to be a complex shape called a “bicontinuous triply periodic minimal surface,” which Torquato recognized from other situations. A minimal surface is one that takes up the least amount of area for a given volume. A soap bubble is a common example of a minimal surface. Usually, this shape arises from a need to minimize surface tension. The researchers were surprised to see a minimal surface in their ideal conductor because neither of their stipulated properties have anything to do with surface tension.

Studying these non-intuitive shapes may offer insights into the relation between structure and function in both biological and man-made materials, Torquato said. “These results and the shapes we found suggest to me that there are incredibly rich opportunities that have not even been tapped into,” he said.

Media Contact

More Information:

http://www.princeton.edu/All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…