Bridge Cable Fails, DuPont™ Hytrel® to the Rescue

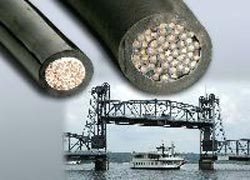

Photo: DuPont <br>Slimmer profile of cable insulated with DuPont™ Hytrel® (left) indicates longer flex life than rubber-insulated cable (right) that failed after less than two years of service on lift bridge.

Because Hytrel® provides effective electrical insulation and toughness in thin layers, the replacement cables using Hytrel® are more than 40 percent smaller in diameter than the one that failed. “Smaller cable diameter means longer flex life at a given bend radius,” said Ted Beach, director of sales for Northwire. Hytrel® is ideal for cables that flex because its combination of high dielectric strength and toughness allows its use in thinner layers than many alternative materials.

The old cable, which used ethylene-propylene rubber for insulation of its 50 conductors (16 AWG), measured 1.86 inches (47 millimeters) in diameter. The diameter of the replacement cable using Hytrel® is about 40 percent smaller, just 1.1 inches (28 millimeters). Its conductors are each insulated with 0.010 inch (0.25 millimeter) of Hytrel®. Another advantage for Hytrel® is productivity and stability during extrusion of such thin insulation layers.

Northwire is also bringing the benefits of Hytrel® for insulation to manufacturers and end-users of robots, other industrial automation equipment and retractable coiled cable for various applications. The company recently obtained the first 90ºC and 105ºC UL recognitions for Hytrel® under the UL 758 standard. These are embodied in UL style 10912 AWM.

Based in Osceola, Wis., Northwire specializes in custom-designed cables for industrial, medical and a variety of specialized markets. For more information, call 1-800-468-1516 or visit http://www.northwire.com.

For more information about DuPont™ Hytrel®, please visit plastics.dupont.com on the web.

The DuPont Engineering Polymers business manufactures and sells Crastin® PBT and Rynite® PET thermoplastic polyester resins, Delrin® acetal resins, Hytrel® thermoplastic polyester elastomers, DuPont™ ETPV engineering thermoplastic vulcanizates, Minlon® mineral reinforced nylon resins, Thermx® PCT polycyclohexylene dimethyl terephthalate, Tynex® filaments, Vespel® parts and shapes, Zenite® LCP liquid crystal polymers, Zytel® nylon resins and Zytel® HTN high-performance polyamides. These products serve global markets in the aerospace, appliance, automotive, consumer, electrical, electronic, healthcare, industrial, sporting goods and many other diversified industries.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 70 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval Logo, DuPont™, The miracles of science™ and Hytrel® are registered trademarks or trademarks of E.I. du Pont de Nemours and Company or its affiliates.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…