Repelling the drop on top

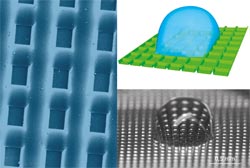

Left: Micrometer-scale structured polystyrene surfaces for use with micro-fluids. Right: Static wetting of this type of surface with water – simulation and experiment. © Fraunhofer IWM<br>

It’s raining cats and dogs and even the short run out to the car leaves your vision obscured by rain on your spectacles. There might soon be no need to reach for a cloth to wipe them off. If the surface of the lens resembled that of a lotus leaf, the drops would all fall off by themselves. The practicality of such self-cleaning surfaces is not limited to eyewear. Corrosion coatings would put up a better fight against rust without the tiny puddles of water that tend to collect on top of them.

But exactly what characterizes surfaces that do the best job of cleaning themselves? Researchers at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg have now developed simulation software that provides the answers. “Our simulation shows how various liquids behave on different surfaces, no matter if these are flat, curved or structured,” explains Dr. Adham Hashibon, project manager at the IWM. The program simulates the form the liquid droplets take on the surface, indicating whether the liquid distributes itself over the surface, or contracts to form droplets in order to minimize contact with the surface. The program is also able to calculate the flow behavior in terms of how liquids move across different surfaces, whereby the determinant factors at different scales of measurement are integrated, from atomic interactions to the impact of microscopic surface structure.

The software analyzes what goes on within a given droplet – how the individual water molecules interact with each other, how a droplet is attracted by the surface and how it resists the air. Researchers refer to a three-phase contact link between liquid, surface and air. “How liquid behaves on a surface is influenced by a great deal of parameters, including the surface characteristics of the material as well as its structure, but also by substances dissolved in the liquid. We have taken all this into account to different degrees of detail within the simulation so that we are able to clearly reproduce our experimental findings,” says Hashibon.

Improving microfluidic systems

The simulation is also useful in medical examinations. When doctors have to analyze tissue cells or parts of DNA, they often use microfluidic systems such as constant-flow cuvettes. Liquid containing dissolved substances is analyzed as it flows through tiny channels and minute chambers, and it is essential that no liquid whatsoever remains after the procedure has been completed. Any residual drops would then mix with a new sample and distort findings. The simulation will now be used to help optimize such microfluidic systems and to design surfaces so that as little liquid as possible gets left behind. “Our goal was to better understand and control the wetting behavior of liquids on structured surfaces,” says Hashibon. But that’s not all. This tool can also be used to implement a kind of traffic management system within the microfluidic system. When a channel splits into two, giving each fork a different surface structure makes it possible to separate the various components of the liquid, sending DNA molecules one way while other components are led along the alternative route. This technique can be used to heighten the concentration of certain molecules and is especially important, for instance, in raising the detection sensitivity of analysis techniques.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…