Process control for fast laser processing of CFRP

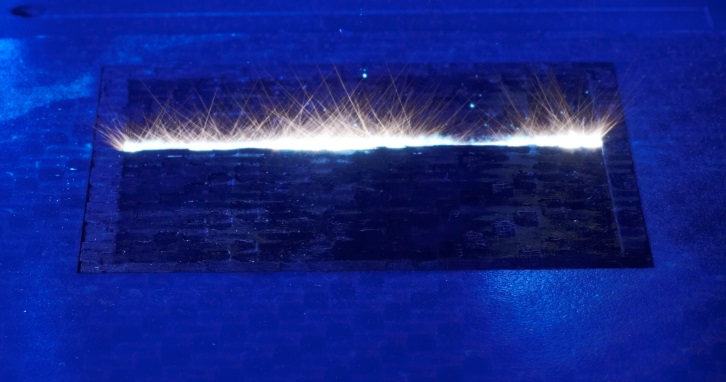

The new measurement method will soon be able to accurately monitor thermally critical areas of the processing geometry. Photo: LZH

Therefore scientists at the Laser Zentrum Hannover e.V. (LZH) are now working together with the Sensortherm GmbH and Newson nv on an innovative double scanner processing head: In this processing head, the beam path of the processing laser is decoupled from the detection beam path used for temperature measurement.

This makes it possible to have spatially flexible and temporally high-resolution measurements during the processing of fiber-reinforced plastic.

The combined scanning head should make it possible to measure any point within or without the laser interaction zone, during the running process. In order to achieve this, the project partners decouple the laser beam path from the path of the high speed pyrometer.

In this process, the measurement beam of the pyrometer will be guided by separate scanner mirrors. These are especially tuned to the detection wavelength of the pyrometer.

Process control for fiber-reinforced plastic materials

Highly accurate online temperature measurement is especially important for laser processing of fiber-reinforced plastic materials, such as carbon fiber reinforced plastics (CFRP). With the combined scanning head and the associated measurement method, thermally critical areas in the processing geometry can be accurately monitored. This principle builds the foundation for active intervention in the process and its optimization.

While the LZH is developing the affiliated laser processes and the process control for welding and cutting of fiber-reinforced plastic materials, Newson nv, Berlare-Overmere, Belgium, is developing the actual combined scanning head.

An innovative, high speed pyrometer for different wavelength ranges is being adapted to this processing head by Sensortherm GmbH, Sulzbach/Taunus. Furthermore, Sensortherm is optimizing this pyrometer for laser transmission welding, and for laser cutting and material removal.

The use of the combined scanning head is not limited to laser processing of fiber-reinforced plastic materials, meaning that metals or glass materials, for example, can also be processed.

The European EraSME project A'Quilaco (Advanced online quality and process control for high speed laser machining of composites) started on January 1st, 2014, and will run for two years. In Germany, A'Quilaco is financially supported by the Federal Ministry for Economic Affairs and Energy (BMWi), and in Belgium by the IWT “agentschap voor Innovatie door Wetenschap en Technologie”.

http://www.lzh.de/en/projects/a-quilaco – project website

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…