ORNL microscopy generates new view of fuel cells

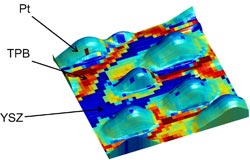

A new ORNL microscopy technique allows researchers to study key reactions in fuel cells at an unprecedented scale. The overlay shows electrochemical activity of platinum (Pt) nanoparticles on an yttria-stabilized zirconia (YSZ) surface, revealing enhanced activity along the triple-phase boundaries (TPB). <br>

ORNL researchers applied a technique called electrochemical strain microscopy that enables them to examine the dynamics of oxygen reduction/evolution reactions in fuel cell materials, which may reveal ways to redesign or cut the costs of the energy devices. The team's findings were published in Nature Chemistry.

“If we can find a way to understand the operation of the fuel cell on the basic elementary level and determine what will make it work in the most optimum fashion, it would create an entirely new window of opportunity for the development of better materials and devices,” said co-author Amit Kumar, a research scientist at ORNL's Center for Nanophase Materials Sciences.

Although fuel cells have long been touted as a highly efficient way to convert chemical energy into electrical energy, their high cost — in large part due to the use of platinum as a catalyst — has constrained commercial production and consumption.

Large amounts of platinum are used to catalyze the fuel cell's key reaction — -the oxygen-reduction reaction, which controls the efficiency and longevity of the cell. Yet exactly how and where the reaction takes place had not been probed because existing device-level electrochemical techniques are ill suited to study the reaction at the nanoscale. ORNL co-author Sergei Kalinin explains that certain methods like electron microscopy had failed to capture the dynamics of fuel cell operation because their resolution was effectively too high.

“When you want to understand how a fuel cell works, you are not interested in where single atoms are, you're interested in how they move in nanometer scale volumes,” Kalinin said. “The mobile ions in these solids behave almost like a liquid. They don't stay in place. The faster these mobile ions move, the better the material is for a fuel cell application. Electrochemical strain microscopy is able to image this ion mobility.”

Other electrochemical techniques are unable to study oxygen-reduction reactions because they are limited to resolutions of 10's of microns – 10,000 times larger than a nanometer.

“If the reaction is controlled by microstructure features that are much finer than a micron, let's say grain boundaries or single extended defects that are affecting the reaction, then you will never be able to catch what is giving rise to reduced or enhanced functionality of the fuel cell,” said ORNL's Stephen Jesse, builder of the ESM microscope. “You would like to do this probing on a scale where you can identify each of these defects and correlate the functionality of the cell with these defects.”

Although this study mainly focuses on the introduction of a technique, researchers explain their approach as a much-needed bridge between a theoretical and applied understanding of fuel cells.

“There is a huge gap between fundamental science and applied science for energy-related devices like fuel cells and batteries,” Kalinin said. “The semiconducting industry, for example, is developing exponentially because the link between application and basic science is very well established. This is not the case in energy systems. They are usually much more complicated than semiconductors and therefore a lot of development is driven by trial and error type of work.”

Co-authors on the study are University of Heidelberg's Francesco Ciucci and Anna Morozovska from the National Academy of Science of Ukraine, whose theoretical analysis was critical in explaining the ESM measurements.

This research was conducted at the Center for Nanophase Materials Sciences at ORNL. CNMS is one of the five DOE Nanoscale Science Research Centers supported by the DOE Office of Science, premier national user facilities for interdisciplinary research at the nanoscale. Together the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE's Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge and Sandia and Los Alamos national laboratories.

For more information about the DOE NSRCs, please visit http://science.energy.gov/bes/suf/user-facilities/nanoscale-science-research-centers/. ORNL is managed by UT-Battelle for the Department of Energy's Office of Science.

Media Contact

More Information:

http://www.ornl.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…