Origins and uses of wrinkles, creases, folds

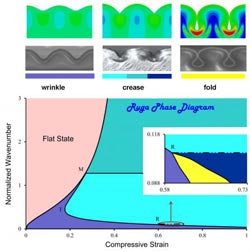

Three ruga states and how they form<br> A phase diagram shows the amount of compressive strain needed to create wrinkles, creases and folds in rubbery materials. The purple area denotes the wrinkle state and the aqua areas are two crease states. The spot marked “R” denotes folding. Credit: Kim lab/Brown University <br>

Engineers from Brown University have mapped out the amounts of compression required to cause wrinkles, creases, and folds to form in rubbery materials. The findings could help engineers control the formation of these structures, which can be useful in designing nanostructured materials for flexible electronic devices or surfaces that require variable adhesion.

“When a rubbery material is compressed and reaches a critical load, it experiences instability and forms surface patterns like wrinkles, creases, or folds,” said Mazen Diab, a postdoctoral researcher in Brown’s School of Engineering and the paper’s first author. “We’re studying how each of those states forms.”

While most of us might use the terms wrinkle, crease, and fold almost interchangeably, engineers recognize distinct properties in each of those states. As defined by the Brown researchers, the wrinkle state is when peaks and troughs start to form on the surface, like waves on the ocean. The crease state is when a distinctly sharp groove is formed on the surface. A fold occurs when the areas on either side of the wrinkle trough begin to touch, forming hollow channels beneath the surface plane of the material.

The researchers refer to these states collectively as “ruga” states, a term originating from Latin and often used in anatomy to describe wrinkle formations in the body such as on the stomach or the roof of the mouth.

Each ruga state could have different implications in a design setting. In a flexible circuit board, for example, wrinkles might be acceptable but creases or folds could cause short circuits. Engineers might use creases or folds to control the adhesive properties of a surface. These structures can hide the area of a sticky surface in troughs, making it less likely to stick. Stretching the surface brings the stickiness back. Folds could be useful in trapping large molecules or nanoparticles and in transporting fluids.

The idea behind this latest research is to understand at what points each ruga state forms, helping engineers to better utilize them. To do that, the researchers used a mathematical model that simulates the deformation characteristics of a layered rubbery material with its elastic property varying with depth from the surface. The result was a phase diagram that pinpoints the precise amounts of compression required to form each ruga state.

The diagram identifies two crease states along with a wrinkle state and a fold state. A setback crease happens when a wrinkle progresses to a crease under additional strain. An instantaneous crease happens when the initial strain is sufficient to skip the wrinkle phase.

“The phase diagram shows the compressive strain needed to form all these ruga states and shows the transitions from one state to another,” said Diab, who works in the lab of professor Kyung-Suk Kim in Brown’s School of Engineering. “Engineers can use it as a guide to get the shapes they want in different length scales.”

Beyond material science, Kim says the work will help scientists “to fathom natural processes observed in broad scales from mountain folds to skin creases and folds of micro organs in biology.”

The research is published in Proceedings of the Royal Society A. Also contributing to the paper were Teng Zhang, Ruike Zhao, and Huajian Gao. The work was supported by the Korea Institute of Machinery and Materials, the Korea Institute of Science and Technology and the U.S. National Science Foundation (DMR-0520651).

Editors: Brown University has a fiber link television studio available for domestic and international live and taped interviews, and maintains an ISDN line for radio interviews. For more information, call (401) 863-2476.

Media Contact

More Information:

http://www.brown.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…