On the Road to Mottronics

Epitaxial mismatches in the lattices of nickelate ultra-thin films can be used to tune the energetic landscape of Mott materials and thereby control conductor/insulator transitions.

“Mottronics” is a term seemingly destined to become familiar to aficionados of electronic gadgets. Named for the Nobel laureate Nevill Francis Mott, Mottronics involve materials – mostly metal oxides – that can be induced to transition between electrically conductive and insulating phases.

If these phase transitions can be controlled, Mott materials hold great promise for future transistors and memories that feature higher energy efficiencies and faster switching speeds than today’s devices. A team of researchers working at Berkeley Lab’s Advanced Light Source (ALS) have demonstrated the conducting/insulating phases of ultra-thin films of Mott materials can be controlled by applying an epitaxial strain to the crystal lattice.

“Our work shows how an epitaxial mismatch in the lattice can be used as a knot to tune the energetic landscape of Mott materials and thereby control conductor/insulator transitions,” says Jian Liu, a post-doctoral scholar now with Berkeley Lab’s Materials Sciences Division, who is the lead author on a paper describing this work in the journal Nature Communications. “Through epitaxial strain, we forced nickelate films containing only a few atomic layers into different phases with dramatically different electronic and magnetic properties. While some of these phases are not obtainable in conventional ways, we were able to produce them in a form that is ready for device development.”

The Nature Communications paper is titled “Heterointerface engineered electronic and magnetic phases of NdNiO3 thin films.” The corresponding author is Jak Chakhalian, a professor of physics at the University of Arkansas. Co-authors are Mehdi Kargarian, Mikhail Kareev, Ben Gray, Phil Ryan, Alejandro Cruz, Nadeem Tahir, Yi-De Chuang, Jinghua Guo, James Rondinelli, John Freeland and Gregory Fiete.

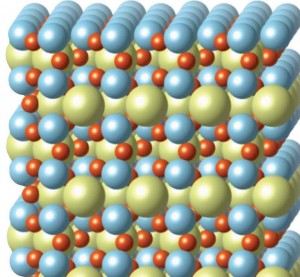

Nickel-based rare-earth perovskite oxides, or “nickelates,” are considered to be an ideal model for the study of Mott materials because they display strongly correlated electron systems that give rise to unique electronic and magnetic properties. Liu and his co-authors studied thin films of neodymium nickel oxide using ALS beamline 8.0.1, a high flux undulator beamline that produces x-ray beams optimized for the study of nanoscale materials and strongly correlated physics.

“ALS beamline 8.0.1 provides the high photon flux and energy range that are critical when dealing with nanoscale samples,” Liu says. “The state-of-the-art Resonant X-ray Scattering endstation has a high-speed, high-sensitivity CCD camera that makes it feasible to find and track diffraction peaks off a thin film that was only six nanometers thick.”

The transition between the conducting and insulating phases in nickelates is determined by various microscopic interactions, some of which favor the conducting phase, some which favor the insulating phase. The energetic balance of these interactions determines how easily electricity is conducted by electrons moving between the nickel and oxygen ions. By applying enough epitaxial strain to alter the space between these ions, Liu and his colleagues were able to tune this energetic balance and control the conducting/insulating transition. In addition, they found strain could also be used to control the nickelate’s magnetic properties, again by exploiting the lattice mismatch.

“Magnetism is another hallmark of Mott materials that often goes hand-in-hand with the insulating state and is used to distinguish Mott insulators,” says Liu. “The challenge is that most Mott insulators, including nickelates, are antiferromagnets that macroscopically behave as non-magnetic materials. “At ALS beamline 8.0.1, we were able to directly track the magnetic evolution of our thin films while tuning the metal-to-insulator transition. Our findings give us a better understanding of the physics behind the magnetic properties of these nickelate films and point to potential applications for this magnetism in novel Mottronics devices.”

This research was primarily supported the U.S. Department of Energy’s Office of Science.

Media Contact

More Information:

http://www.lbl.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…