NYU’s Microscopic Monitoring May Yield Big Advances in Production of Consumer Products & Pharmaceuticals

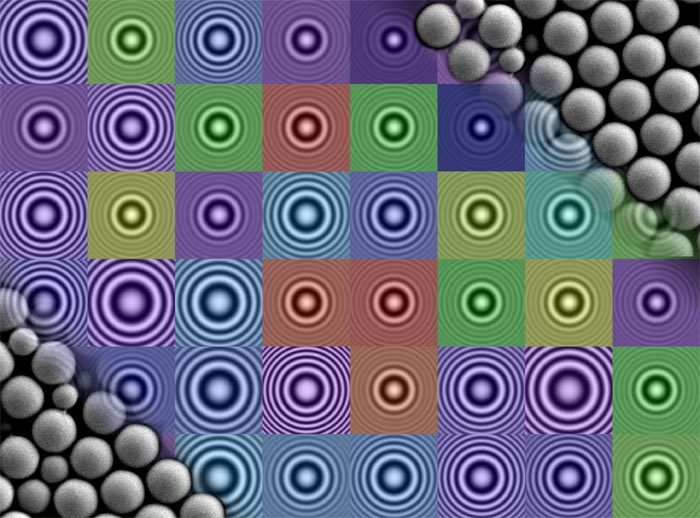

David Grier Holograms of individual spheres such as the examples shown here were used to improve the manufacturing process that created the silicone-rubber spheres shown in the grey-scale images.

“We can now look at each of the particles in a developing dispersion to see how the chemical reaction is progressing and whether the particles are turning out the way they should,” explains NYU Physics Professor David Grier, one of the paper’s authors and director of the university’s Center for Soft Matter Research.

Previously, scientists could not look inside a growing microparticle and understand the nature of the material it was composed of—Is the particle fully dense or is it porous? Are all the particles growing in the same way, or are some different from others?

“In the past, there was no way to know these answers because we could not characterize particles’ makeup,” Grier explains. “Now we can.”

The work reported in Soft Matter relies on a technique, holographic video microscopy, which was developed in Grier’s lab at NYU in 2007. It uses a laser beam to create holographic images of individual particles using conventional video cameras and digital video recorders to record the data.

The researchers novel analysis of these digitized holograms yields an unprecedented wealth of information about the positions and properties of the individual particles within the sample. This information, in turn, reveals how well the reaction is progressing and what steps should be taken to optimize its products.

To demonstrate the capabilities of their technique, the researchers studied the synthesis of crosslinked polydimethysiloxane (PDMS) spheres—compounds that make up silicone.

However, Grier says, the procedure could be applied to particles that comprise many consumer products.

“If a cosmetics company wants to add a new fragrance to its products or a pharmaceutical company needs to change the active ingredients of a drug, they need to add new chemical compounds,” Grier explains. “But how will they interact? How will this change the consistency of the product? And, especially in the case of drug development, will they be effective?

“This procedure shows that we now have the potential understand this process at the most fundamental level, which would enhance both product design and production.”

Holographic characterization provides insights into the properties of products that will enhance their safety, functionality, and consistency, and will reduce costs by improving process control and eliminating the need for trial-and-error testing, Grier says. His group’s proof-of-concept demonstration is being brought to the market by Spheryx, Inc. (http://spheryx.solutions/), which has exclusively licensed NYU’s technology for holographic characterization.

The paper’s other authors are: Chen Wang, a doctoral student in NYU’s Department of Physics; NYU Physics Professor Andrew Hollingsworth; and Hagay Shpaisman, an NYU post-doctoral fellow at the time of the study and now a Senior Lecturer at Israel’s Bar-Ilan University.

The research was supported by grants from Procter & Gamble and NASA (NNX13AR67G) as well as by the National Science Foundation under its MRSEC (DMR-1420073) and MRI (DMR-0923251) programs. The article describing this work is published in Soft Matter, volume 11, pages 1062 – 1066, February 14, 2015.

Contact Information

James Devitt

Deputy Director for Media Relations

james.devitt@nyu.edu

Phone: 212-998-6808

Media Contact

More Information:

http://www.nyu.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…