New Implanted Devices May Reshape Medicine

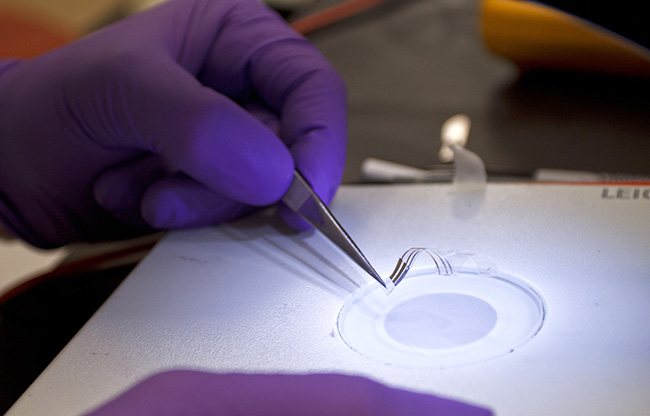

When heated, the devices can change shape and still maintain their electronic properties. Click on the image to watch the transistor flex its gripping ability.

Researchers from The University of Texas at Dallas and the University of Tokyo have created electronic devices that become soft when implanted inside the body and can deploy to grip 3-D objects, such as large tissues, nerves and blood vessels.

These biologically adaptive, flexible transistors might one day help doctors learn more about what is happening inside the body, and stimulate the body for treatments.

The research, available online and in an upcoming print issue of Advanced Materials, is one of the first demonstrations of transistors that can change shape and maintain their electronic properties after they are implanted in the body, said Jonathan Reeder BS’12, a graduate student in materials science and engineering and lead author of the work.

“Scientists and physicians have been trying to put electronics in the body for a while now, but one of the problems is that the stiffness of common electronics is not compatible with biological tissue,” he said. “You need the device to be stiff at room temperature so the surgeon can implant the device, but soft and flexible enough to wrap around 3-D objects so the body can behave exactly as it would without the device. By putting electronics on shape-changing and softening polymers, we can do just that.”

Shape memory polymers developed by Dr. Walter Voit, assistant professor of materials science and engineering and mechanical engineering and an author of the paper, are key to enabling the technology.

The polymers respond to the body’s environment and become less rigid when they’re implanted. In addition to the polymers, the electronic devices are built with layers that include thin, flexible electronic foils first characterized by a group including Reeder in work published last year in Nature.

The Voit and Reeder team from the Advanced Polymer Research Lab in the Erik Jonsson School of Engineering and Computer Science fabricated the devices with an organic semiconductor but used adapted techniques normally applied to create silicon electronics that could reduce the cost of the devices.

“We used a new technique in our field to essentially laminate and cure the shape memory polymers on top of the transistors,” said Voit, who is also a member of the Texas Biomedical Device Center. “In our device design, we are getting closer to the size and stiffness of precision biologic structures, but have a long way to go to match nature’s amazing complexity, function and organization.”

The rigid devices become soft when heated. Outside the body, the device is primed for the position it will take inside the body.

During testing, researchers used heat to deploy the device around a cylinder as small as 2.25 millimeters in diameter, and implanted the device in rats. They found that after implantation, the device had morphed with the living tissue while maintaining excellent electronic properties.

“Flexible electronics today are deposited on plastic that stays the same shape and stiffness the whole time,” Reeder said. “Our research comes from a different angle and demonstrates that we can engineer a device to change shape in a more biologically compatible way.”

The next step of the research is to shrink the devices so they can wrap around smaller objects and add more sensory components, Reeder said.

UT Dallas researchers and materials engineers Taylor Ware, David Arreaga-Salas and Adrian Avendano-Bolivar were also involved in the study. Ware completed his PhD in 2013 and performs fundamental research on liquid crystalline polymers at the Air Force Research Labs.

The work was funded by the National Science Foundation Graduate Research Fellowship, NSF East Asia and Pacific Summer Institute, the Japan Science and Technology Agency, CONACYT (Consejo Nacional de Ciencia y Tecnología) Fellowship program and the Defense Advanced Research Projects Agency (DARPA) Young Faculty Award program.

Media Contact: LaKisha Ladson, UT Dallas, (972) 883-4183, lakisha.ladson@utdallas.edu

or the Office of Media Relations, UT Dallas, (972) 883-2155, newscenter@utdallas.edu

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…