Nanowires: The long and short of breaking

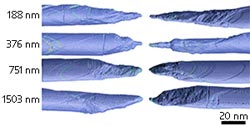

Examples of failure in four different lengths of nanowire as a result of tensile stress. Only nanowire sections close to the fracture are shown. A short (188 nanometer (nm)) nanowire fails through gradual, ductile deformation (top). A long (1,503 nm) nanowire fails abruptly through a brittle or localized shear failure (bottom).<br><br>© 2012 American Chemical Society<br>

Most materials will break when a force is applied to an imperfection in their structure — such as a notch or dislocation. The behavior of these imperfections, and the resulting breakage, differ markedly between small structures, such as nanowires, and larger, bulk materials.

However, scientists lacked complete understanding of the precise mechanics of nanowire breakages, owing in part to inconsistent behavior in experiments. These inconsistencies are now resolved thanks to numerical simulations by Zhaoxuan Wu and his co-workers at the A*STAR Institute for High Performance Computing, Singapore, and collaborators in the USA1.

The researchers focused on metal nanowires with a so-called 'face-centered cubic crystal structure' because they exhibit two different failure modes. Previous experiments by other groups showed that these nanowires can break as the result of a ductile process, in which a narrow neck is formed smoothly and continuously before failure. Other experiments showed that the failure was caused by a brittle fracture, which happened suddenly. To complicate matters further, atom-scale simulations of these experiments predicted that only ductile necking should be occurring.

Most materials will break when a force is applied to an imperfection in their structure — such as a notch or dislocation. The behavior of these imperfections, and the resulting breakage, differ markedly between small structures, such as nanowires, and larger, bulk materials. However, scientists lacked complete understanding of the precise mechanics of nanowire breakages, owing in part to inconsistent behavior in experiments. These inconsistencies are now resolved thanks to numerical simulations by Zhaoxuan Wu and his co-workers at the A*STAR Institute for High Performance Computing, Singapore, and collaborators in the USA (1).

The researchers focused on metal nanowires with a so-called 'face-centered cubic crystal structure' because they exhibit two different failure modes. Previous experiments by other groups showed that these nanowires can break as the result of a ductile process, in which a narrow neck is formed smoothly and continuously before failure. Other experiments showed that the failure was caused by a brittle fracture, which happened suddenly. To complicate matters further, atom-scale simulations of these experiments predicted that only ductile necking should be occurring.

The A*STAR-affiliated researchers contributing to this research are from the Institute for High Performance Computing

Journal information

Wu, Z., Zhang, Y.-W., Jhon, M. H., Gao, H. & Srolovitz, D. J. Nanowire failure: long = brittle and short = ductile. Nano Letters 12, 910–914 (2012).

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…