Nanomaterials: Copying geckos’ toes

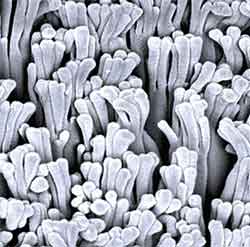

Artificial hairs just a few hundred nanometers in diameter mimic the adhesive surface of a gecko’s toe-pads. Copyright : Agency for Science, Technology and Research <br>

Geckos are famous for their ability to walk up walls and scamper across ceilings. The dry-adhesive surface of geckos’ toes has inspired many attempts to copy this ability in an artificial material. Isabel Rodríguez at the A*STAR Institute of Materials Research and Engineering and co-workers at Nanyang Technological University in Singapore1 have now made one of the closest mimics to gecko toes yet, and shown that it has the properties to match.

The geckos’ ability to cling to surfaces is not due to glue but to the millions of microscopic hairs that coat the surface of their toes. Each hair has a branched, hierarchical structure—toward its tip, each fiber breaks into multiple sub-fibers, which in turn break into hundreds of fibrils 100–200 nanometers in diameter. This structure ensures a high surface area, which helps the gecko to cling to the wall. In addition, the hairs become more flexible as they become thinner, which helps to maximize the number of fibrils in contact with the wall.

Rodríguez and her co-workers have successfully mimicked this hierarchical structure through the use of an anodization technique that allows branched nanopores to be etched controllably into sheets of aluminium foil—a process they used to form templates with which to create the dry adhesive surface. These templates were stamped into sheets of polycarbonate plastic using a process known as capillary force-assisted nanoimprinting, forming a hairy polycarbonate surface.

To evaluate the qualities of the hierarchical hair structure, the researchers created two separate surfaces: one with simple, unbranched hairs; and one in which the hairs branched at their tips to form nanoscopic fibrils (pictured) closely resembling those found on gecko toe-pads. They found that the sheer adhesion force of the branched material was 150% greater than that of the linear material.

“One of the most important findings from the study is the insight of how the fibrils can be made using a simple process,” says Rodríguez. “There have been reports of other hierarchical structures fabricated in polymers, but the fabrication methods they use are rather costly and complicated and not suitable for large scale.” The relatively high cost of previous attempts is due to the way the template is made—a problem that the team have now overcome using their porous alumina template technology. “Our branched, porous template fabrication is straightforward and allows large areas of gecko-like structures to be fabricated at low cost,” she adds.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering

References

Ho, A. Y. Y., Yeo, L. P., Lam, Y. C. & Rodríguez, I. Fabrication and analysis of gecko-inspired hierarchical polymer nanosetae. ACS Nano 5, 1897–1906 (2011).

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…