New microfluidic approach for the directed assembly of functional materials

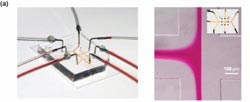

An optical micrograph of the microchannel junction with red dye flow-focused in water shows experimental conditions used for nanostructure assembly.<br>

According to Charles Schroeder, an assistant professor in the Department of Chemical and Biomolecular Engineering, the results show that peptide precursor materials can be aligned and oriented during their assembly into polypeptides using tailored flows in microfluidic devices.

The research was a collaboration between the labs of Schroeder and William Wilson, a research professor in materials science and engineering and the Frederick Seitz Materials Research Laboratory at Illinois. Their findings were recently published in a paper entitled, “Fluidic-directed assembly of aligned oligopeptides with pi-conjugated cores” in Advanced Materials.

“A grand challenge in the field of materials science is the ability to direct the assembly of advanced materials for desired functionality,” says Amanda Marciel, a graduate student in Schroeder’s research group. “However, design of new materials is often hindered by our inability to control the structural complexity of synthetic polymers.”

“To address the need for controlled processing of functional materials, we developed a microfluidic-based platform to drive the assembly of synthetic oligopeptides,” Marciel explained. “Using a microfluidic device, we assembled DFAA and DFAG into one dimensional nanostructures using a planar extensional flow generated in a cross-slot geometry.”

The dynamics of the assembly process can be followed in real-time using fluorescence microscopy and spectroscopy.

“The assembled nanostructure is spectrally distinct from the synthetic oligopeptide monomer, which can be used to monitor the dynamics of nanostructure formation,” Marciel added. “Using precise hydrodynamic control of the microfluidic platform, the researchers demonstrated the formation of multiple parallel-aligned synthetic oligopeptide nanostructures and their subsequent disassembly. By modulating volumetric flow rates in the device they were able to manipulate the position of the fluid-fluid interface at the microchannel junction.

During this process, nanostructures initially formed at the reactive laminar interface are submerged into the advancing acidic stream, thereby preserving the integrity of the preformed nanostructures while initiating formation of an aligned nanostructure at the new interface position.

Marciel says this research shows that is possible to use microfluidic-based flows to direct the structural assembly of polymers into functional materials.

“Our approach has the potential to enable reproducible and reliable fabrication of advanced materials.” Marciel said. “Achieving nanoscale ordering in assembled materials has become the primary focus of recent efforts in the field. These approaches will ultimately lead to desired morphology in functional materials, which will enhance their ability to capture and store energy.”

“Our research team is quite interdisciplinary and has a unique range of skills to study materials assembly,” Schroeder said. “Our group has extensive experience in the design and fabrication of microfluidic devices and fluorescence imaging of soft materials.” The team’s ultimate goal is to assemble the organic equivalent of typical semiconducting materials.

“This would open the door to developments of materials with application to photovoltaic devices, solid-state lighting, energy harvesting, and catalytic processes,” she said.

In addition to Marciel, Schroeder, and Wilson, the paper's authors included, Melikhan Tanyeri, Brian D. Wall, and John D. Tovar. The team used spectroscopic and analytical tools at the Frederick Seitz Materials Research Lab to conduct its research.

Contact: Charles M. Schroeder, Department of Chemical & Biomolecular Engineering, University of Illinois at Urbana-Champaign, 217/333-3906.

Writer: Sarah Williams, assistant director of communications, Department of Chemical and Biomolecular Engineering, 217/244-0541.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…