Mapping the behavior of charges in correlated spin-orbit coupled materials

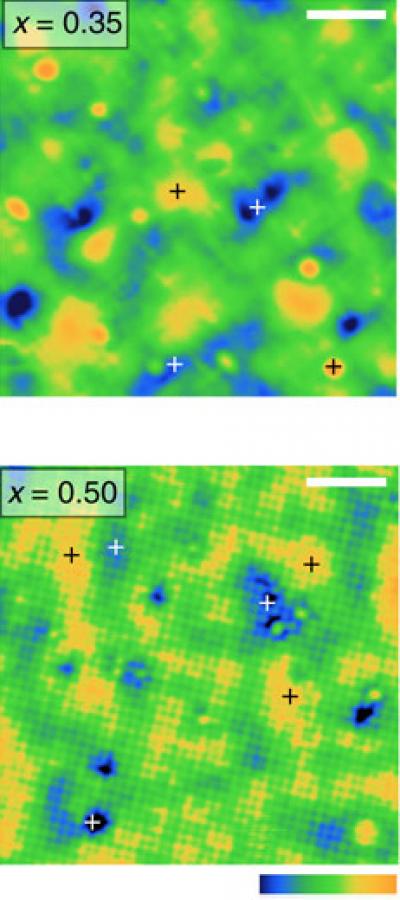

Images obtained through scanning tunneling spectroscopy show the transformation of a compound of strontium, iridium and oxygen -- part of a mysterious class of materials known as spin-orbit Mott insulators. By introducing charge carriers within the compound by replacing 40 percent of the iridium ions with ruthenium, researchers from Boston College were able to reveal the microscopic mechanisms that transform these insulators into a metallic state. The images reveal ruthenium effectively created features within the compound that resembled minute metallic puddles. As the amount of additional ruthenium was increased, the puddles 'percolate,' coalescing to form a metal across which charges freely flow. Credit: Nature Communications

In a relatively recently discovered class of materials, known as spin-orbit Mott insulators, theorists have predicted the emergence of new properties at points just beyond the insulating state, when electronic manipulation can transform these compounds into conducting metals.

A better understanding of electrons near this transition, theorists have predicted, could allow these new Mott insulators to pave the way to discoveries in superconductivity, new topological phases of matter, and new forms of unusual magnetism.

What scientists have lacked is experimental evidence that reveals the microscopic mechanisms that actually drive one of these spin-orbit Mott insulators to become a metal.

Now a team of physicists at Boston College report in Nature Communications that they manipulated a compound of strontium, iridium and oxygen – Sr3Ir207 – with a substitution of ruthenium metal ions, successfully driving the material into the metallic regime, and mapping this previously uncharted transformation as it took place, giving scientists a unique view into the workings of these insulators.

Spin-orbit Mott insulators are so named because of their complex electronic properties. Within these novel materials, there is a repulsive interaction between electrons that tends to drive the electrons to a stand still. This tendency is bolstered by the lowering of the electron's energy via a strong interaction between the electron's magnetic field and its orbital motion around the nucleus.

This delicate interplay between repulsive action, known as Coulomb interaction, and the coupling between electrons' spin and orbital motion has allowed scientists to define this class of materials as spin-orbit Mott insulators.

Boston College Assistant Professor of Physics Stephen D. Wilson said the team succeeded in driving the insulator-to-metal transformation by replacing 40 percent of the iridium ions with ruthenium, thereby creating a metal alloy. That event introduced charge carriers, which have proven successful in destabilizing the so-called Mott phase in the transformation of compounds in this class of insulators.

Scanning tunneling microscopy revealed ruthenium effectively created features within the compound that resembled minute metallic puddles, said Wilson, one of the lead researchers on the project. As the amount of additional ruthenium was increased, the puddles began to “percolate,” coalescing to form a metal across which charges freely flow, he added.

“The addition of ruthenium introduces charge carriers, but at a low ratio of ruthenium to iridium they simply stay put in these little metallic puddles, which are symptoms of strong correlated electrons,” Wilson said. “These electrons are stable and wouldn't move much. But when we stepped up the disruption by increasing the amount of ruthenium, the puddles moved together and achieved a metallic state.”

The behavior in this particular compound parallels what researchers have seen in Mott insulators that play host to such phenomenon as high temperature superconductivity, said Wilson, who will discuss his research at the upcoming annual meeting of the American Physical Society.

By pinpointing exactly where this transformation takes place, the team's findings should help to lay the groundwork in the scientific search for new electronic phases within spin-orbit Mott insulators, said Wilson, who co-authored the report with his Boston College Department of Physics colleagues Professor Vidya Madhavan, Professor Ziqiang Wang, and Assoc. Prof. Fr. Cyril P. Opeil, SJ.

BC graduate students Chetan Dhital, the lead author of the paper, Tom Hogan, Wenwen Zhou, Xiang Chen, Zhensong Ren, Mani Pokharel, and M. Heine also contributed to the project. Scientists at the Oak Ridge National Laboratory, the U.S. National Institute of Standards and Technology and the Canadian Center for Neutron Research also collaborated on the research.

Media Contact

More Information:

http://www.bc.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…

Rocks with the oldest evidence yet of Earth’s magnetic field

The 3.7 billion-year-old rocks may extend the magnetic field’s age by 200 million years. Geologists at MIT and Oxford University have uncovered ancient rocks in Greenland that bear the oldest…

Decisive breakthrough for battery production

Storing and utilising energy with innovative sulphur-based cathodes. HU research team develops foundations for sustainable battery technology Electric vehicles and portable electronic devices such as laptops and mobile phones are…