New magnetic-field-sensitive alloy could find use in novel micromechanical devices

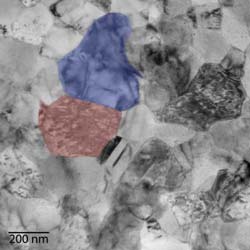

This is a transmission electron microscope image taken at NIST of an annealed cobalt iron alloy. The high magnetostriction seen in this alloy is due to the two-phase iron-rich (shaded blue) and cobalt-rich (shaded red) structure and the nanoscale segregation. Credit: Bendersky/NIST<br>

The alloy, a combination of cobalt and iron, is notable, among other things, for not using rare-earth elements to achieve its properties. Materials scientists at the National Institute of Standards and Technology (NIST) contributed precision measurements of the alloy's structure and mechanical properties to the project.

The alloy exhibits a phenomenon called “giant magnetostriction,” an amplified change in dimensions when placed in a sufficiently strong magnetic field. The effect is analogous to the more familiar piezoelectric effect that causes certain materials, like quartz, to compress under an electric field. They can be used in a variety of ways, including as sensitive magnetic field detectors and tiny actuators for micromechanical devices. The latter is particularly interesting to engineers because, unlike piezoelectrics, magnetostrictive elements require no wires and can be controlled by an external magnetic field source.

To find the best mixture of metals and processing, the team used a combinatorial screening technique, fabricating hundreds of tiny test cantilevers — tiny, 10-millimeter-long, silicon beams looking like diving boards — and coating them with a thin film of alloy, gradually varying the ratio of cobalt to iron across the array of cantilevers. They also used two different heat treatments, including, critically, one in which the alloy was heated to an annealing temperature and then suddenly quenched in water.

Quenching is a classic metallurgy technique to freeze a material's microstructure in a state that it normally only has when heated. In this case, measurements at NIST and the Stanford Synchrotron Radiation Lightsource (SSRL) showed that the best-performing alloy had a delicate hetereogenous, nanoscale structure in which cobalt-rich crystals were embedded throughout a different, iron-rich crystal structure. Magnetostriction was determined by measuring the amount by which the alloy bent the tiny silicon cantilever in a magnetic field, combined with delicate measurements at NIST to determine the stiffness of the cantilever.

The best annealed alloy showed a sizeable magnetostriction effect in magnetic fields as low as about 0.01 Tesla. (The earth's magnetic field generally ranges around roughly 0.000 045 T, and a typical ferrite refrigerator magnet might be about 0.7 T.)

The results, says team leader Ichiro Takeuchi of UMd, are lower than, but comparable to, the values for the best known magnetostrictive material, a rare-earth alloy called Tb-Dy-Fe** — but with the advantage that the new alloy doesn't use the sometimes difficult to acquire rare earths. “Freezing in the heterogeneity by quenching is an old method in metallurgy, but our approach may be unique in thin films,” he observes. “That's the beauty — a nice, simple technique but you can get these large effects.”

The quenched alloy might offer both size and processing advantages over more common piezoelectric microdevices, says NIST materials scientist Will Osborn. “Magnetorestriction devices are less developed than piezoelectrics, but they're becoming more interesting because the scale at which you can operate is smaller,” he says. “Piezoelectrics are usually oxides, brittle and often lead-based, all of which is hard on manufacturing processes. These alloys are metal and much more compatible with the current generation of integrated device manufacturing. They're a good next-generation material for microelectromechanical machines.”

The effort also involved researchers from the Russian Institute of Metal Physics, Urals Branch of the Academy of Science; Oregon State University and Rowan University. Funding sources included the Office of Naval Research and the National Science Foundation. SSRL is part of the SLAC National Accelerator Laboratory, operated under the auspices of the U.S. Department of Energy.

* D. Hunter, W. Osborn, K. Wang, N. Kazantseva, J. Hattrick-Simpers, R. Suchoski, R. Takahashi, M.L. Young, A. Mehta, L.A. Bendersky, S.E. Lofland, M. Wuttig and I. Takeuchi. Giant magnetostriction in annealed Co1-xFex thin-films. Nature Communications. Nov. 1, 2011. DOI: 10.1038/ncomms1529

** Terbium-dysprosium-iron

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…