Lightweight Construction Materials of Highest Stability Thanks to Their Microarchitecture

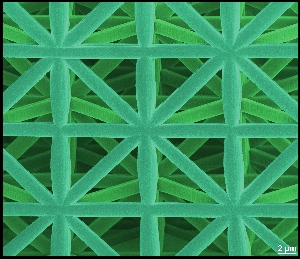

The framework construction made of a ceramic-polymer composite is highly stable, although the individual elements have a thickness of a few hundred nanometers only. (Picture: J. Bauer/KIT)

KIT researchers have developed microstructured lightweight construction materials of highest stability. Although their density is below that of water, their stability relative to their weight exceeds that of massive materials, such as high-performance steel or aluminum.

The lightweight construction materials are inspired by the framework structure of bones and the shell structure of the bees’ honeycombs. The results are now presented in the journal PNAS, DOI: 10.1073/pnas.1315147111.

“The novel lightweight construction materials resemble the framework structure of a half-timbered house with horizontal, vertical, and diagonal struts,” says Jens Bauer, Karlsruhe Institute of Technology (KIT). “Our beams, however, are only 10 µm in size.” In total, the lightweight construction elements are about 50 µm long, wide, and high.

“Nature also uses open-pore, non-massive structures for carrying loads,” Oliver Kraft, KIT, explains. Examples are wood and bones. At the same density, however, the novel material produced in the laboratory can carry a much higher load.

A very high stability was reached by a shell structure similar to the structure of honeycombs. It failed at a pressure of 28 kg/mm2 only and had a density of 810 kg/m3. This exceeds the stability / density ratio of bones, massive steel, or aluminum. The shell structure produced resembles a honeycomb with slightly curved walls to prevent buckling.

To produce the lightweight construction materials, 3D laser lithography was applied. Laser beams harden the desired microstructure in a photoresist. Then, this structure is coated with a ceramic material by gas deposition. The structures produced were subjected to compression via a die to test their stability.

Microstructured materials are often used for insulation or as shock absorbers. Open-pore materials may be applied as filters in chemical industry.

High-strength cellular ceramic composites with 3D microarchitecture, Jens Bauer, Stefan Hengsbach, Iwiza Tesari, Ruth Schwaiger, and Oliver Kraft, PNAS Early Edition, DOI: 10.1073/pnas.1315147111

Karlsruhe Institute of Technology (KIT) is a public corporation according to the legislation of the state of Baden-Württemberg. It fulfills the mission of a university and the mission of a national research center of the Helmholtz Association. Research activities focus on energy, the natural and built environment as well as on society and technology and cover the whole range extending from fundamental aspects to application. With about 9000 employees, including nearly 6000 staff members in the science and education sector, and 24000 students, KIT is one of the biggest research and education institutions in Europe. Work of KIT is based on the knowledge triangle of research, teaching, and innovation.

PKM, Themenscout

Tel.: +49 721 608-41956

Fax: +49 721 608-43568

E-Mail:schinarakis@kit.edu

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…

Innovative microscopy demystifies metabolism of Alzheimer’s

Researchers at UC San Diego have deployed state-of-the art imaging techniques to discover the metabolism driving Alzheimer’s disease; results suggest new treatment strategies. Alzheimer’s disease causes significant problems with memory,…

A cause of immunodeficiency identified

After stroke and heart attack: Every year, between 250,000 and 300,000 people in Germany suffer from a stroke or heart attack. These patients suffer immune disturbances and are very frequently…