Using Light, Researchers Convert 2-D Patterns Into 3-D Objects

Soft Matter (Nov. 10, 2011)<br>Michael Dickey, North Carolina State University<br>The new technique can be used to create a variety of objects, such as cubes or pyramids, without ever having to physically touch the material.<br>

“This is a novel application of existing materials, and has potential for rapid, high-volume manufacturing processes or packaging applications,” says Dr. Michael Dickey, an assistant professor of chemical and biomolecular engineering at NC State and co-author of a paper describing the research.

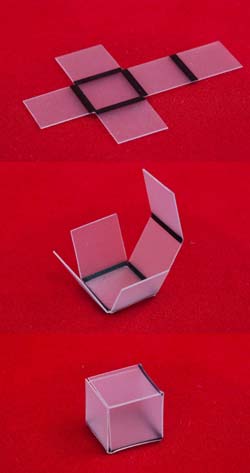

The process is remarkably simple. Researchers take a pre-stressed plastic sheet and run it through a conventional inkjet printer to print bold black lines on the material. The material is then cut into a desired pattern and placed under an infrared light, such as a heat lamp. A video demonstration is available at http://www.youtube.com/watch?v=NKRWZG67dtQ

The bold black lines absorb more energy than the rest of the material, causing the plastic to contract – creating a hinge that folds the sheets into 3-D shapes. This technique can be used to create a variety of objects, such as cubes or pyramids, without ever having to physically touch the material. The technique is compatible with commercial printing techniques, such as screen printing, roll-to-roll printing, and inkjet printing, that are inexpensive and high-throughput but inherently 2-D.

By varying the width of the black lines, or hinges, researchers are able to change how far each hinge folds. For example, they can create a hinge that folds 90 degrees for a cube, or a hinge that folds 120 degrees for a pyramid. The wider the hinge, the further it folds. Wider hinges also fold faster, because there is more surface area to absorb energy.

“You can also pattern the lines on either side of the material,” Dickey says, “which causes the hinges to fold in different directions. This allows you to create more complex structures.”

The researchers developed a computer-based model to explain how the process works. There were two key findings. First, the surface temperature of the hinge must exceed the glass transition temperature of the material, which is the point at which the material begins to soften. Second, the heat has to be localized to the hinge in order to have fast and effective folding. If all of the material is heated to the glass transition temperature, no folding will occur.

“This finding stems from work we were doing on shape memory polymers, in part to satisfy our own curiosity. As it turns out, it works incredibly well,” Dickey says.

The paper, “Self-folding of polymer sheets using local light absorption,” was published Nov. 10 in the journal Soft Matter, and was co-authored by Dickey; NC State Celanese Professor of Chemical and Biomolecular Engineering Jan Genzer; NC State Ph.D. student Ying Liu; and NC State undergraduate Julie Boyles. The work was supported, in part, by the U.S. Department of Energy.

Dr. Michael Dickey, (919) 513-0273 or michael_dickey@ncsu.edu

Dr. Jan Genzer, (919) 515-2069 or jan_genzer@ncsu.edu

Matt Shipman, NC State News Services, (919) 515-6386 or matt_shipman@ncsu.edu

Media Contact

More Information:

http://www.ncsu.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…