Improved electrical and mechanical performance for insulating intricate electronics

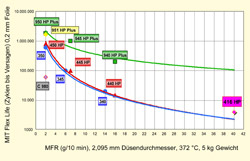

Image: DuPont<br>Whereas standard PFAs with a melt flow rate (MFR) of 40 g/10 min would be situated on the blue or red line, DuPont™ Teflon® PFA 416 HP has been specifically designed to provide a higher MIT flexlife (approximately 4000 cycles to failure) at such elevated rates of flow. <br>

DuPont Fluoropolymer Solutions has announced the commercial availability of a new perfluoroalkoxy-based resin for insulation of wire, cable and intricate electronic parts. The new fluoropolymer resin, DuPont™ Teflon® PFA 416HP, features a high melt-flow rate while maintaining very good MIT flex life.

These characteristics offer coaxial wire manufacturers, semiconductor OEMs and electronic device designers the ability to coat ultra-thin gauge wire and to injection-mold fine, intricate thin-wall parts in a more efficient manner than can be done with other fluoropolymers. DuPont™ Teflon® PFA 416HP resin provides all of the advantages of PTFE – including ultra-high thermal resistance and dielectric properties – and combines those critical attributes with a very high melt-flow rate.

These inherent characteristics enable almost transparent coatings on ultra-fine wire, such as the kind used in mobile telephones, medical sensor wires, micro coaxial cables, and wireless antenna applications in headsets, laptops and smart phones. Teflon® PFA 416HP also provides excellent chemical resistance, very good stress crack resistance and easy flow for molding applications. “Our new PFA resin is a breakthrough, high-performance product innovation that opens up even more options for fine wire applications where maximum flexibility and high thermal resistance are needed,” said Jacob Lahijani, Ph.D., senior technical consultant – DuPont Fluoropolymer Solutions.

“Ultra-high thermal resistance in insulation means that highly intricate electronics can be insulated with an extremely thin, almost transparent coating and still withstand soldering. With the higher melt-flow rate, this new resin broadens the ability to injection-mold fine, intricate parts as well.” DuPont™ Teflon® PFA 416HP is ideally suited for applications such as antennae for wireless electronics, medical probe cables, micro HDMI cables, internal wire harnesses for electronics, and other uses where high melt-flow rate, very low viscosity and high stress crack resistance are critical.To obtain product information and learn more about applications for PFA resins, visit www.dupont.com/416HP.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 90 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval Logo, DuPont™, The miracles of science™ and Teflon® are trademarks or registered trademarks of DuPont or its affiliates. Editorial contact:

Horst Ulrich Reimer

Public Relations Manager Europe, Middle East, Africa

Performance Chemicals & Fluoroproducts

Tel.: +49 (0) 6102 18-1297

Fax: +49 (0) 6102 18-1318

Mobile: +49 (0) 170 915 8742

horst-ulrich.reimer@dupont.com

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…