HIPS fireproof coatings can really take the heat

HIPS coatings can withstand temperatures of over 1000°C compared to current commercial coatings used on building materials and structures which break down at between 150-250°C.

HIPS coatings contain an inorganic geopolymer resin, and a small component of polymer additives.

Project leader, Dr Damian Fullston of CSIRO Materials Science and Engineering, says CSIRO is seeking coatings manufacturers interested in partnering with CSIRO to customise HIPS to meet product specifications for selected applications.

“They are not only fire-, blast- and acid-resistant, they are also strong, castable, sprayable, and extrudable, making their potential uses almost limitless.”“Geopolymers are an emerging class of ceramic-like inorganic polymers produced at room temperatures that have the potential to transform the building products industry,” Dr Fullston says.

“They are not only fire-, blast- and acid-resistant, they are also strong, castable, sprayable, and extrudable, making their potential uses almost limitless.”

“The polymer additives in HIPS improve the flexibility and waterproofing properties, and provide stronger adhesion, which are important properties for a coating.”

HIPS has the potential to form thin fireproof coatings on timbers such as weatherboards, and on metals such as structural or galvanised steel. It can also protect brickwork, either as a thin coating or as a render. HIPS can be applied by spray equipment, roller or brush, and cures from ambient temperature to below 90°C.

As water-based products, HIPS coatings are free of volatile organic compounds, do not burn or produce heat, and do not release smoke or toxic chemicals at temperatures up to 1200°C.

Geopolymers are cost-competitive, since they are made from readily available raw materials. They can also be derived from industrial by-products such as flyash and blast furnace slag. They can be cheaper than organic resins and coloured with pigments or dyes.

The strength of HIPS materials is comparable with that of phenolic resins in heat-sensitive applications, but HIPS retains higher strength at higher temperatures. HIPS formulations are tailored to be interchangeable with phenolic resins, and have higher fatigue resistance than normal phenolics.

CSIRO also sees potential for the manufacture of fireproof wood composites and fire seals from HIPS technology, but has not fully explored these applications to date.

Media Contact

More Information:

http://www.csiro.auAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

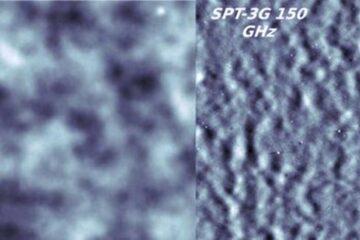

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…