Glass That Bends but Doesn’t Break

François Barthelat<br><br>Bio-inspired glass 200 times tougher than regular glass<br>

Normally when you drop a drinking glass on the floor it shatters. But, in future, thanks to a technique developed in McGill’s Department of Mechanical Engineering, when the same thing happens the glass is likely to simply bend and become slightly deformed.

That’s because Prof. François Barthelat and his team have successfully taken inspiration from the mechanics of natural structures like seashells in order to significantly increase the toughness of glass.

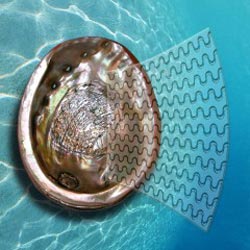

“Mollusk shells are made up of about 95 per cent chalk, which is very brittle in its pure form,” says Barthelat. “But nacre, or mother-of-pearl, which coats the inner shells, is made up of microscopic tablets that are a bit like miniature Lego building blocks, is known to be extremely strong and tough, which is why people have been studying its structure for the past twenty years.”

Previous attempts to recreate the structures of nacre have proved to be challenging, according to Barthelat. “Imagine trying to build a Lego wall with microscopic building blocks. It’s not the easiest thing in the world.” Instead, what he and his team chose to do was to study the internal ‘weak’ boundaries or edges to be found in natural materials like nacre and then use lasers to engrave networks of 3D micro-cracks in glass slides in order to create similar weak boundaries. The results were dramatic.

The researchers were able to increase the toughness of glass slides (the kind of glass rectangles that get put under microscopes) 200 times compared to non-engraved slides. By engraving networks of micro-cracks in configurations of wavy lines in shapes similar to the wavy edges of pieces in a jigsaw puzzle in the surface of borosilicate glass, they were able to stop the cracks from propagating and becoming larger. They then filled these micro-cracks with polyurethane, although according to Barthelat, this second process is not essential since the patterns of micro-cracks in themselves are sufficient to stop the glass from shattering.

The researchers worked with glass slides simply because they were accessible, but Barthelat believes that the process will be very easy to scale up to any size of glass sheet, since people are already engraving logos and patterns on glass panels. He and his team are excited about the work that lies ahead for them.

“What we know now is that we can toughen glass, or other materials, by using patterns of micro-cracks to guide larger cracks, and in the process absorb the energy from an impact,” says Barthelat. “We chose to work with glass because we wanted to work with the archetypal brittle material. But we plan to go on to work with ceramics and polymers in future. Observing the natural world can clearly lead to improved man-made designs.”

Media Contact

More Information:

http://www.mcgill.caAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…