Fraunhofer IFAM is developing de-icing technologies for aircraft with European and Japanese partners

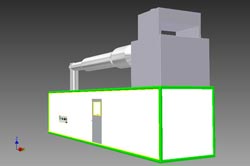

Schematic representation of the Fraunhofer IFAM wind tunnel in which icing tests under realistic conditions will be carried out in the future. (© Fraunhofer IFAM) <br>

This work is being undertaken in an international project with European and Japanese partners. The objective is to develop an integrated system comprising three synergistic components: Active de-icing technology, functional coatings which assist the de-icing function, and sensor technology which not only monitors the icing in real-time but also the de-icing.

The surfaces of aircraft are prone to icing during flights due to the fact that they are exposed to extremely low temperatures (down to -50 degrees Celsius at altitudes of up to 10,000 meters) and also water in the atmosphere, for example in clouds and precipitation.

The formation of ice, particularly on the wings, can lead to enormous problems due to its adverse effect on the aerodynamics and due to its weight. Besides causing higher fuel consumption and greater CO2 emissions, the ice is also a risk to the safety of an aircraft: e. g. for 1998 to 2007, the Federal Aviation Administration (FAA) in the USA recorded in its database a total of 886 incidents related to icing (G. L. Dillingham, AVIATION SAFETY – Preliminary Information on Aircraft Icing and Winter Operations. United States Government Accountability Office. Testimony before the Subcommittee on Aviation, Committee on Transportation and Infrastructure, House of Representatives (GAO-10-441T, February 2010)).

For this reason, an enormous amount of work is current being undertaken on the early detection of ice formation, the suppression of ice formation, and the removal of any ice. For example, waste heat from the engines is being utilized to heat the front edges of the wings. Other de-icing systems are based on mechanical ice removal using so-called “rubber boots”. These rubber boots have air chambers which can be pumped up when needed to remove the ice from the surface.

The JEDI ACE (Japanese-European De-Icing Aircraft Collaborative Exploration) project, which was started in November 2012, aims to develop a multicomponent de-icing system suitable for the next generation of aircraft that are being built using, amongst other things, lightweight carbon fiber reinforced plastics (CFRPs). The focus here is on safety and efficiency aspects. “The new system will require considerably less energy than current system, due to the combination of innovative de-icing technologies and real-time sensors, and will decrease the number of icing-related in-flight incidents by up to 80 percent”, says Gerhard Pauly of the Fraunhofer IFAM who is managing the international project.

Fraunhofer IFAM researchers are involved with the development of coatings and testing the icing properties of the surfaces. These coatings will assist the current de-icing technologies that are based on thermal and/or mechanical principles, by reducing the adhesion of the ice and so making its removal easier. As such, the efficiency of overall de-icing will be significantly improved. “The challenge is to ensure that the coatings remain effective for several years despite the high stress on the aircraft caused by, amongst other things, erosion and UV radiation and we are at present developing coating systems that have this long-term stability”, explains coating expert Nadine Rehfeld of the Fraunhofer IFAM who is the scientific leader of the international project. In addition, the suitability of so-called “shape memory materials” as mechanical actuators is being studied which – when incorporated into a coating – allow ice removal by changing the surface profile. The first results on this were presented at a project meeting in Tokyo in May 2013 attended by a number of project partners: Dassault Aviation (France), University Rovira i Virgili/Centre for University Studies in Aviation (Spain), Fuji Heavy Industries Aerospace Company (Japan), Japan Aerospace Exploration Agency (Japan), and Kanagawa Institute of Technology (Japan). The next phase of the project work was also discussed at this meeting.

Another project goal within JEDI ACE is the construction of a wind tunnel by scientists from the Fraunhofer IFAM. This will enable newly developed de-icing systems to be tested under icing conditions. “Temperatures of -30 degrees Celsius and wind speeds of up to 350 kilometers per hour will be able to be attained in this tunnel. This will allow us to simulate real conditions, including with supercooled water which is also present in liquid form at temperatures below 0 degrees Celsius”, explains Nadine Rehfeld.

The project is being funded by the European Commission and the Japanese Ministry of Economy, Trade and Industry (METI). The Fraunhofer IFAM is leading the scientific work and coordinating the project.

Partners of the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in the JEDI ACE project are

• Dassault Aviation (France)

• University Rovira i Virgili/Centre for University Studies in Aviation (Spain)

• Fuji Heavy Industries Aerospace Company (Japan)

• Japan Aerospace Exploration Agency (Japan)

• Kanagawa Institute of Technology (Japan)

Contact

Paris Air Show Le Bourget 2013 I 17 to 23 June 2013 I Paris I France

Hall 1 I Booth G 316

Gerhard Pauly I Michael Wolf

Media Contact

More Information:

http://www.ifam.fraunhofer.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…

Rocks with the oldest evidence yet of Earth’s magnetic field

The 3.7 billion-year-old rocks may extend the magnetic field’s age by 200 million years. Geologists at MIT and Oxford University have uncovered ancient rocks in Greenland that bear the oldest…

Decisive breakthrough for battery production

Storing and utilising energy with innovative sulphur-based cathodes. HU research team develops foundations for sustainable battery technology Electric vehicles and portable electronic devices such as laptops and mobile phones are…