Engineered biomaterial could improve success of medical implants

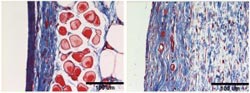

Lei Zhang, UW<br><br>These images show differences in collagen build-up in two tissue samples. Collagen is labeled in blue. The left image shows a thick collagen wall forming in the presence of a material that’s widely used for implantable devices. In contrast, collagen in the right image is more evenly dispersed in the tissue after the UW-engineered hydrogel has been implanted.<br>

Expensive, state-of-the-art medical devices and surgeries often are thwarted by the body’s natural response to attack something in the tissue that appears foreign. Now, University of Washington engineers have demonstrated in mice a way to prevent this sort of response. Their findings were published online this week in the journal Nature Biotechnology.

The UW researchers created a synthetic substance that fully resists the body’s natural attack response to foreign objects. Medical devices such as artificial heart valves, prostheses and breast implants could be coated with this polymer to prevent the body from rejecting an implanted object.

“It has applications for so many different medical implants, because we literally put hundreds of devices into the body,” said Buddy Ratner, co-author and a UW professor of bioengineering and of chemical engineering. “We couldn’t achieve this level of excellence in healing before we had this synthetic hydrogel.”

The body’s biological response to implanted devices – medical technologies that often cost millions to develop – has frustrated experts for years. After an implant, the body usually creates a protein wall around the medical device, cutting it off from the rest of the body. Scientists call this barrier a collagen capsule. Collagen is a protein that’s naturally found in our bodies, particularly in connective tissues such as tendons and ligaments.

If a device such as an artificial valve or an electrode sensor is blocked off from the rest of the body, it usually fails to work. Physicians and scientists have tried to minimize this, but they haven’t been able to eliminate it, Ratner said.

Ratner’s collaborator and co-author Shaoyi Jiang, a UW professor of chemical engineering, and his team implanted the polymer substance into the bodies of mice. The substance is known as a hydrogel, a flexible biomedical material swollen with water. It’s made from a polymer that has both a positive and negative charge, which serves to deflect all proteins from sticking to its surface. Scientists have found that proteins appearing on the surface of a medical implant are the first signs that a larger collagen wall will form.

After three months, Jiang and his team found that collagen was loosely and evenly distributed in the tissue around the polymer, suggesting that the mice bodies didn’t even detect the polymer’s presence.

For humans, the first three weeks after an implant are the most critical, because by then the body will show signs of isolating the implant by building a collagen wall. If this hasn’t happened in the first several weeks, it’s likely the body won’t default to an attack response toward the object.

“Scientists have tried many materials, and with no exception, this is the first non-porous, synthetic substance demonstrating that no collagen capsule forms, which could have positive implications for implantable materials, tissue scaffolds and medical devices,” Jiang said.

UW researchers and others have worked for nearly 20 years to find a way to help the body accept implants. In 1996, the National Science Foundation-funded UW Engineered Biomaterials (UWEB) research center opened at the UW, with Ratner serving as director. Since that time, researchers have been trying to make a material that is invisible to the body’s immune response and could eliminate the body’s negative reaction to medical implants.

Now, nearly two decades years later, engineers have found the “perfect” substance, Ratner said.

“This hydrogel is not just pretty good, it’s exceptional,” he said.

The UW researchers plan to test this in humans, likely by working with manufacturers to coat an implantable device with the polymer, then measure its ability to ward off protein build-up.

The research was funded by the U.S. Office of Naval Research, UWEB and the UW Department of Chemical Engineering.

For more information, contact Ratner at ratner@uw.edu or 206-685-1005 and Jiang at sjiang@uw.edu. Jiang is traveling this week and is available by email.

Media Contact

More Information:

http://www.uw.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…