Development of Coating Method that Accelerates Bonding with Bone by 3 Times

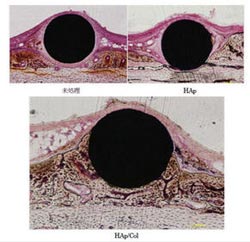

FigureFPhotographs of tissue preparation during 4 weeks after surgery. In the upper 2 photos, soft tissue (dyed pink) exists between titanium material (black) and bone tissue (dyed brown); however, with the HAp/Col in the lower photos, direct bonding has occurred between the material and the bone.<br>

Dr. Masanori Kikuchi, Group Leader of the Bioceramics Group, International Center for Materials Nanoarchitectonics (MANA) and a research group at Tokyo Medical and Dental University succeeded in developing a coating method which accelerates bonding with bone by 3 times.

Dr. Masanori Kikuchi, Group Leader of the Bioceramics Group, International Center for Materials Nanoarchitectonics (MANA; Director-General: Masakazu Aono), National Institute for Materials Science (President: Sukekatsu Ushioda), and a research group including Masayoshi Uezona (graduate student), Prof. Kazuo Takakuda (Institute of Biomaterials and Bioengineering), Prof. Keiji Moriyama (School of Dentistry, Maxillofacial Orthognathics), and others at Tokyo Medical and Dental University (President; Takashi Ohyama) succeeded in developing a coating which accelerates bonding with bone by 3 times.

Orthodontic subperiosteal devices are superior in terms of low invasiveness, but because bonding with bone on the surface of the bone is necessary, a minimum waiting time of approximately 3 months had been required until medical use was possible, even when coating treatment was performed with hydroxy apatite (HAp).

In order to shorten this time, the device shape was optimized and a new coating method was developed in joint work by NIMS and Tokyo Medical and Dental University. As a result, a coating method which realizes in only 1 month the same bone coverage as after 3 months with the conventional device was established.

Journal information

This research result was published online on April 2, US time, in the Journal of Biomedical Materials Research Part B: Applied Biomaterials.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…