Custom-Built Infrared Emitters for Printed Electronic Components

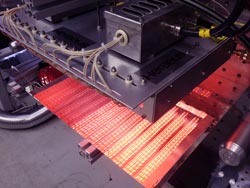

One custom-built infrared system can carry out several different drying and sintering processes. Copyright Heraeus Noblelight GmbH, Hanau 2013<br>

Printed electronic components and printed features of electronic products are very much on the increase, providing RFID (radio frequency identification), as integral features of telephone- and credit cards (smart cards), providing protection against copying or as security features in identity cards and passes.

To produce such printed electronic components, organic or metallized inks are applied to plastic foils, paper or glass. By curing, drying and sintering, the required conductive properties are achieved and at the same time the coating is firmly joined to the base material.

A newly developed infrared system, including an intelligent control unit, meets all important requirements, and this new module was shown for the first time at the LOPE-C exhibition which took place in June.

All conventional printing processes, such as screen printing, inkjet, gravure and Flexo, can be used to produce printed electronic components. The inks used are organic or metallized inks and these can be used with many materials such as paper, plastic foil or glass. Curing, drying and sintering are processes necessary to obtain the required conductivity or the semi-conducting or dielectric properties. These processes can be carried out by UV emitters, LEDs, flash lamps, hot air ovens or infrared systems.

According to which type of ink and base material is used, and which type of printing is employed (sheet-fed or offset), the manufacturer must generally replace the curing/drying/sintering source module, or install several different modules.

An innovative infrared system, including an intelligent control unit, can minimize this time wasting effort as several different drying and sintering processes can be carried with the aid of a single, custom-built infrared system. This new infrared solution is available in two versions, to allow an individual matching of the system with the ink, material, printing process and feed speed.

Version 1 employs an infrared module which is fitted with only one type of emitter. Here the requirements for the different applications are realized by means of an intelligent control unit.

Version 2 features a single infrared module fitted with various types of emitter matched to the heating zones of several drying and sintering zones. Both versions provide controllable infrared power density in the range 20 to 220kW/m2. Emitter filament temperatures are from 1,200 to 3,000°C, so that the infrared spectrum can be optimally matched with the reflection and absorption characteristics of the inks and the substrates. The optimum distance between emitter and product is also important. With tests feed speeds of up to 60 meters per minute have been be achieved.

With both infrared system versions it is no longer necessary to change the emitter, module or other components when changing over between different processes. This significantly raises a system’s productivity.

Infrared Systems Offer Significant Advantages in Printing Electronic Products.

Infrared emitters transfer energy in a contact-free manner and generate energy only in the product to be heated. They can be excellently matched with different functional materials and substrates in terms of wavelength, power and shape. Very fast response times minimize material damage in the event of unexpected feed belt stoppage or breakage.

Modern numerical methods such as Ray tracing and Computational Fluid Dynamics (CFD) are used to ensure that heating is as homogenous as possible. The energy distribution over the material surface can be optimized, for example, by carrying out simulations prior to installation. Sophisticated reflector technology also helps to ensure that the energy is applied in the best way possible.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with more than 160 years of tradition. Our fields of competence include precious metals, materials and technologies, sensors, biomaterials and medical products, quartz glass, and specialty light sources. In the financial year 2012 Heraeus generated product revenues of €4.2 billion and precious metal trading revenues of €16 billion. With more than 12,200 employees in over 100 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources. In 2012, Heraeus Noblelight had an annual turnover of 92,5 Million € and employed 715 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters and systems for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

Heraeus Noblelight acquired on January 31, 2013 the Fusion UV Systems group headquartered in Gaithersburg, Maryland (USA).

For further information contact:

Reader:

Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press:

Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

More Information:

http://www.heraeus-noblelight.com/infraredAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…