Creating a water layer for a clearer view

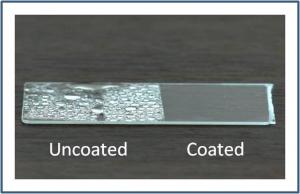

Photo showing the effectiveness of CleanClear:The uncoated section (left) of a glass slide is peppered with water droplets whereas the coated section (right) has a thin film of water that makes the glass clear.

When it comes to fogged up glassware or windows, the best way to keep a clear view seems to be by wiping the water droplets away constantly or having coatings that prevent the water from sticking to the glass. However, scientists at A*STAR’s Institute of Materials Research and Engineering (IMRE) have discovered that doing just the opposite – collecting the water to create a uniform, thin, transparent layer – actually helps produce a better, clearer view.

IMRE has invented a new technology, CleanClear, which is a durable and permanent ceramic coating that is transparent and superhydrophilic, which means it attracts water instead of repelling it. This creates a layer of water that prevents fogging on glass or plastic surfaces, and keeps surfaces cleaner for a longer period of time. Water-forming coatings create an additional uniform water layer to produce a better view as opposed to water-repelling technologies that form water droplets which impair vision.

Reduced visibility from fogged up glass or plastic surfaces is a common problem in wet or humid environments, and affects a multitude of products such as car windshields, spectacles, goggles, and even covers for cookware. The majority of solutions rely on water-repelling coatings. Unfortunately, current coatings are not durable and most have to be re-applied regularly.

How the technology works

The new patented technology from A*STAR’s IMRE is a one-time ceramic coating that can be applied onto glass or plastic materials at processing temperatures below 100oC. This is important as it makes the coating process simpler and ultimately, more cost-effective. Currently, commonly used chemical coatings degrade easily with continued usage and have to be re-applied. IMRE’s new ceramic coating is durable, permanent and only needs to be applied once. Although there are also other similar “water-loving” coatings, these are often processed at much higher temperatures and can only be activated by ultraviolet (UV) rays or sunlight.

Large multinational companies also use alternative coatings like titanium dioxide (TiO2) to produce self-cleaning glass surfaces that prevent dirt and dust from sticking. However, the TiO2 ceramic coats can only be applied on surfaces during the manufacturing process at temperatures above 600oC. This limits their application to hard materials like glass. CleanClear can be adapted to multiple surfaces and materials, ranging from glass to plastics. TiO2 coatings are also activated by sunlight but IMRE’s new coating does not require activation and continues to function even at night and in low-light, indoor environments.

There are many useful applications for IMRE’s “water-loving” surface. For example, it can be applied on car windshields, mirrors and motorcycle visors, allowing for better visibility in the rain. Coating building exteriors with this new material allows for self-cleaning during rain. Due to its adaptability for application on various surfaces besides glass, this could also result in potential cost savings. CleanClear can also be applied to consumer products to reduce condensation on glass covers for pots, food containers and hot food displays.

“Conventional technologies mainly use organic-based materials and some with nanoparticles but these don’t last long, and need to be re-coated from time to time. The CleanClear process makes the coating part of the surface – permanently,” said Dr Gregory Goh, the lead scientist from IMRE who developed the technology last year.

“CleanClear could be used to help create a sort of a clear ‘vision shield’ for today’s car windshields during heavy rain,” added Dr Goh. “Or we could use it to replace current daytime, UV light activated coatings with an all-day, all-night CleanClear coat on building facades to keep glass cleaner.”

IMRE is in talks with companies to further develop and license the technology.

For media queries and clarifications, please contact:

Eugene Low

Senior Manager, Corporate Communications

Agency for Science, Technology and Research

Tel: +65 6874 8491

Email: loweom@scei.a-star.edu.sg

About the Institute of Materials Research and Engineering (IMRE)

The Institute of Materials Research and Engineering (IMRE) is a research institute of the Agency for Science, Technology and Research (A*STAR). The Institute has capabilities in materials analysis & characterisation, design & growth, patterning & fabrication, and synthesis & integration. We house a range of state-of-the-art equipment for materials research including development, processing and characterisation. IMRE conducts a wide range of research, which includes novel materials for organic solar cells, photovoltaics, printed electronics, catalysis, bio-mimetics, microfluidics, quantum dots, heterostructures, sustainable materials, atom technology, etc. We collaborate actively with other research institutes, universities, public bodies, and a wide spectrum of industrial companies, both globally and locally.

For more information about IMRE, please visit www.imre.a-star.edu.sg

About the Agency for Science, Technology and Research (A*STAR)

The Agency for Science, Technology and Research (A*STAR) is Singapore's lead public sector agency that fosters world-class scientific research and talent to drive economic growth and transform Singapore into a vibrant knowledge-based and innovation driven economy.

In line with its mission-oriented mandate, A*STAR spearheads research and development in fields that are essential to growing Singapore’s manufacturing sector and catalysing new growth industries. A*STAR supports these economic clusters by providing intellectual, human and industrial capital to its partners in industry.

A*STAR oversees 18 biomedical sciences and physical sciences and engineering research entities, located in Biopolis and Fusionopolis, as well as their vicinity. These two R&D hubs house a bustling and diverse community of local and international research scientists and engineers from A*STAR’s research entities as well as a growing number of corporate laboratories.

For more information on A*STAR, please visit www.a-star.edu.sg

Associated links

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…