Components based on nature's example

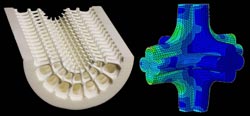

The picture on the left shows a lightweight structure made of polyamide inspired by bionic principles. The picture on the right shows its detailed simulation on the computer. Credit: Fraunhofer IWM<br>

Long bones, for instance, consist of a compact, solid outer casing filled with spongy tissue, which makes them particularly strong and resilient. Researchers from the Fraunhofer Institutes for Mechanics of Materials IWM and for Environmental, Safety and Energy Technology UMSICHT are collaborating on a project entitled “Bionic Manufacturing”, which aims to develop products that are lightweight but strong and economic in their use of materials – imitating the perfected structures found in nature.

The IWM scientists in Freiburg have taken on the task of identifying the best internal structures for manufactured components. “We have set ourselves the challenge of working as efficiently as nature: The finished component must not weigh more than necessary and yet still be able to perform its mechanical function reliably,” explains Dr. Raimund Jaeger of IWM. This approach can be combined with a high degree of creative freedom: “Such components can be used to produce consumer goods with a high aesthetic value, such as designer chairs,” adds Jaeger. And if by chance one of these bionically designed objects should break as the result of excessive loading, it will do so in a benign way – collapsing smoothly in localized areas rather than shattering into sharp splinters.

Whereas natural materials have evolved over numerous generations to reach the level of perfection we see today, engineers and product designers have to work much faster. The Freiburg research team has therefore developed a new design method. They start by constructing a virtual model of the future workpiece on the computer, filling out its contours with almost identical, cube-shaped, elementary cells. If the numerical simulation reveals that the grid structure does not satisfy requirements, the cell walls (trabecular microstructure) are refined accordingly. “We make them thicker if they are too weak and thinner if they need to be more pliable, or align them with the force lines along which the load is distributed,” explains Jaeger. This method enables many different shapes to be designed around an inner cell structure that can then be evaluated and optimized using the simulation tool. To complement the simulations, the researchers carry out tests on real-life components to verify the structure's mechanical properties.

Jaeger reports that the method has worked very well every time they have used it to design any type of workpiece based on two-dimensional templates that can be pulled into the desired shape using the computer simulation. The same applies to components with a relatively regular shape. Despite their light weight, all of these components are very strong and resilient and capable of absorbing even substantial shocks. According to the scientists, they have potential applications wherever there is a need for products that combine a high level of mechanical stability and aesthetic appearance with low weight – for example medical orthopedic devices or anatomically formed body protectors such as lumbar support belts for skiers.

Fraunhofer UMSICHT is responsible for the technical implementation of the bionic design principles. The solution chosen by the project managers in Oberhausen involves the use of additive manufacturing techniques – in this case selective laser sintering of polymer materials. This technique enables workpieces to be fabricated by laying down successive layers of a fine polyamide powder, which are fused together in the desired configuration using a focused laser beam. It is the ideal method for creating complex internal structures and, at a later stage, components with a distributed pattern of material properties, which experts refer to as functionally graded materials. The resulting structures are similar to those observed in nature.

Media Contact

More Information:

http://www.iwm.fraunhofer.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…