Carbon-fiber epoxy honeycombs mimic the material performance of balsa wood

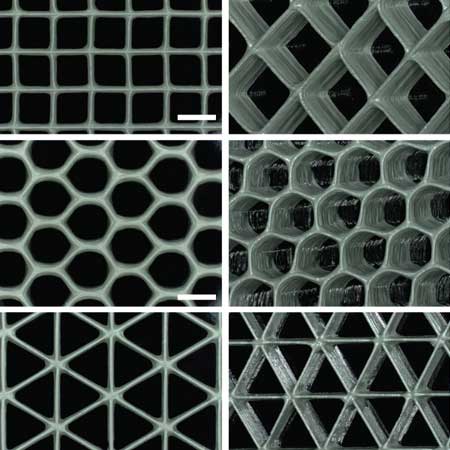

Materials scientists at Harvard SEAS have developed cellular composite materials of unprecedented light weight and stiffness. (Image courtesy of Brett G. Compton, Harvard University.)

In wind farms across North America and Europe, sleek turbines equipped with state-of-the-art technology convert wind energy into electric power. But tucked inside the blades of these feats of modern engineering is a decidedly low-tech core material: balsa wood.

Like other manufactured products that use sandwich panel construction to achieve a combination of light weight and strength, turbine blades contain carefully arrayed strips of balsa wood from Ecuador, which provides 95 percent of the world’s supply.

For centuries, the fast-growing balsa tree has been prized for its light weight and stiffness relative to density. But balsa wood is expensive and natural variations in the grain can be an impediment to achieving the increasingly precise performance requirements of turbine blades and other sophisticated applications.

As turbine makers produce ever-larger blades—the longest now measure 75 meters, almost matching the wingspan of an Airbus A380 jetliner—they must be engineered to operate virtually maintenance-free for decades. In order to meet more demanding specifications for precision, weight, and quality consistency, manufacturers are searching for new sandwich construction material options.

Now, using a cocktail of fiber-reinforced epoxy-based thermosetting resins and 3D extrusion printing techniques, materials scientists at the Harvard School of Engineering and Applied Sciences (SEAS) and the Wyss Institute for Biologically Inspired Engineering have developed cellular composite materials of unprecedented light weight and stiffness. Because of their mechanical properties and the fine-scale control of fabrication (see video), the researchers say these new materials mimic and improve on balsa, and even the best commercial 3D-printed polymers and polymer composites available.

A paper describing their results has been published online in the journal Advanced Materials.

Until now, 3D printing has been developed for thermo plastics and UV-curable resins—materials that are not typically considered as engineering solutions for structural applications. “By moving into new classes of materials like epoxies, we open up new avenues for using 3D printing to construct lightweight architectures,” says principal investigator Jennifer A. Lewis, the Hansjörg Wyss Professor of Biologically Inspired Engineering at Harvard SEAS. “Essentially, we are broadening the materials palette for 3D printing.”

“Balsa wood has a cellular architecture that minimizes its weight since most of the space is empty and only the cell walls carry the load. It therefore has a high specific stiffness and strength,” explains Lewis, who in addition to her role at Harvard SEAS is also a Core Faculty Member at the Wyss Institute. “We’ve borrowed this design concept and mimicked it in an engineered composite.”

Lewis and Brett G. Compton, a former postdoctoral fellow in her group, developed inks of epoxy resins, spiked with viscosity-enhancing nanoclay platelets and a compound called dimethyl methylphosphonate, and then added two types of fillers: tiny silicon carbide “whiskers” and discrete carbon fibers. Key to the versatility of the resulting fiber-filled inks is the ability to control the orientation of the fillers.

The direction that the fillers are deposited controls the strength of the materials (think of the ease of splitting a piece of firewood lengthwise versus the relative difficulty of chopping on the perpendicular against the grain).

Lewis and Compton have shown that their technique yields cellular composites that are as stiff as wood, 10 to 20 times stiffer than commercial 3D-printed polymers, and twice as strong as the best printed polymer composites. The ability to control the alignment of the fillers means that fabricators can digitally integrate the composition, stiffness, and toughness of an object with its design.

“This paper demonstrates, for the first time, 3D printing of honeycombs with fiber-reinforced cell walls,” said Lorna Gibson, a professor of materials science and mechanical engineering at the Massachusetts Institute of Technology and one of world’s leading experts in cellular composites, who was not involved in this research. “Of particular significance is the way that the fibers can be aligned, through control of the fiber aspect ratio—the length relative to the diameter—and the nozzle diameter. This marks an important step forward in designing engineering materials that mimic wood, long known for its remarkable mechanical properties for its weight.”

“As we gain additional levels of control in filler alignment and learn how to better integrate that orientation into component design, we can further optimize component design and improve materials efficiency,” adds Compton, who is now a staff scientist in additive manufacturing at Oak Ridge National Laboratory. “Eventually, we will be able to use 3D printing technology to change the degree of fiber filler alignment and local composition on the fly.

The work could have applications in many fields, including the automotive industry where lighter materials hold the key to achieving aggressive government-mandated fuel economy standards. According to one estimate, shedding 110 pounds from each of the 1 billion cars on the road worldwide could produce $40 billion in annual fuel savings.

3D printing has the potential to radically change manufacturing in other ways too. Lewis says the next step will be to test the use of thermosetting resins to create different kinds of architectures, especially by exploiting the technique of blending fillers and precisely aligning them. This could lead to advances not only in structural materials, but also in conductive composites.

Previously, Lewis has conducted groundbreaking research in the 3D printing of tissue constructs with vasculature and lithium-ion microbatteries.

Primary support for the cellular composites work came from the BASF North American Center for Research on Advanced Materials at Harvard.

Additional support was provided by the Materials Research Science and Engineering Center at Harvard, funded by the National Science Foundation (DMR 0820484).

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…