Bioglass helping to mend bones

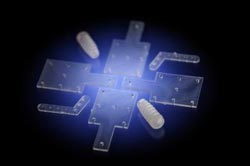

These are implants made of biodegradable polymers, Department of Materials Science and Engineering, Faculty of Technical Engineering in Bilbao (UPV/EHU).<br><br>Credit: UPV/EHU<br>

Jose Ramon Sarasua and Aitor Larrañaga, researchers in the materials engineering department of the UPV/EHU-University of the Basque Country, have been studying new materials or implants that are of interest in medicine and in helping to mend bones, in particular.

They have in fact measured the effect that the bioglass has on the thermal degradation of polymers currently used in medicine. The results have been published in the journal Polymer Degradation and Stability.

Bones are capable of regenerating themselves if they suffer slight damage. But if the damage is above a certain degree, bone lacks the capability of mending itself. When breaks are too big, bones need to be helped. Even today, metal nails or other components are often inserted to help these breaks to mend. So, once the bone has mended, a second operation has to be performed to extract these components. The aim of these new materials or implants is, among other things, to obviate the need for the second operation.

These materials or implants that are of interest in medicine have to meet a number of requirements before they can be used in therapeutic applications. Among other things, the materials have to be biocompatible, in other words, they must not damage the cells or the organism itself. At the same time, being biodegradable is also a very interesting property, so that the body will easily convert them into metabolic products that are not toxic. But other factors also have to be taken into consideration: mechanical robustness and the straightforward nature of the production process, for example.

Tailor-made materials

With all this in mind, the UPV/EHU researchers are synthesising and shaping tailor-made bioimplants. The main component, on the whole, tends to be a biodegradable polymer, in other words, one that will gradually disappear as the bone occupies its own place. As the polymer is too soft, bioglass was added to the polymer in this piece of work. Bioglass is a bioactive agent and helps the bone to regenerate; what is more, it gives the polymer tough mechanical properties. So the biodegradable polymer/bioglass composite system is stiffer and tougher than the polymer alone.

These composite systems can be manufactured by means of thermoplastic processes that use heat, and therefore it is important to study how these materials respond to heat. In this work, the biodegradable polymer/bioglass composite systems were found to have a lower thermal stability compared with the systems without bioglass. In fact, a reaction occurs between the silicon oxide ions of the bioglass and the carbonyl groups in the polymers' structure, and so the material degrades and adversely affects the properties of the end product, and what is more, when the implant is grafted into the body, it encourages the formation of bi-products that may be harmful for the cells. This would greatly restrict the application of these systems in medicine. That is why the UPV/EHU researchers are doing a lot of research to improve the thermal stability of these systems, and they have in fact published one of these pieces of work in the journal Polymer Degradation and Stability. In this case, they are proposing that a chemical transformation of the bioglass surface be made by means of plasma. So by creating protective layers for the bioglass particles, the reaction to the polymer is prevented and so the final product remains undamaged.

So “these composites that have a biodegradable polymer base are candidates with a bright future in mending broken bones or in regenerating bone defects,” says Professor Sarasua. In fact, after the material has temporarily substituted the bone and encouraged it to regenerate, it gradually disappears as the bone returns to its proper place. So, “this obviates the need for the second operations required nowadays to remove nails and other parts that are inserted in order to somehow support the bones in major breaks above a critical size, with all the advantages that has from a whole range of perspectives,” he added.

Article reference

A.Larrañaga, Jose-Ramon Sarasua. Effect of bioactive glass particles on the thermal degradation behaviour of medical polyesters. Polymer Degradation and Stability. 98:751-758 (2013).

About the authors

Jose Ramon Sarasua-Oiz and Aitor Larrañaga-Espartero lecture and do research at the Faculty of Technical Engineering in Bilbao (UPV/EHU). They are also the director and member, respectively, of the ZIBIO (Science & Engineering of Polymeric Biomaterials) research team, which is part of the Basque Excellence Research Center for Macromolecular Design & Engineering (Polymat).

Media Contact

More Information:

http://www.elhuyar.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…