Biocompatible graphene transistor array reads cellular signals

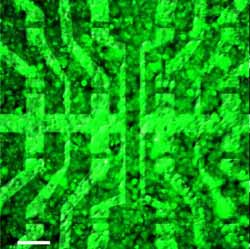

This combination of optical microscopy and fluorescence imaging shows a layer of biological cells covering a graphene-based transistor array. The experimental device, created by scientists from the Technische Universitaet Muenchen and the Juelich Research Center, is the first of its kind to prove capable of recording signals generated by living cells, with good spatial and temporal resolution. With this demonstration, the researchers have opened the way to further investigation of the feasibility of using graphene-based bioelectronics for potential future applications such as neuroprosthetic implants in the brain, the eye, or the ear. Credit: Copyright TU Muenchen<br>

Researchers have demonstrated, for the first time, a graphene-based transistor array that is compatible with living biological cells and capable of recording the electrical signals they generate. This proof-of-concept platform opens the way for further investigation of a promising new material.

Graphene's distinctive combination of characteristics makes it a leading contender for future biomedical applications requiring a direct interface between microelectronic devices and nerve cells or other living tissue. A team of scientists from the Technische Universitaet Muenchen and the Juelich Research Center published the results in the journal Advanced Materials.

Today, if a person has an intimate and dependent relationship with an electronic device, it's most likely to be a smart phone; however, much closer connections may be in store in the foreseeable future. For example, “bioelectronic” applications have been proposed that would place sensors and in some cases actuators inside a person's brain, eye, or ear to help compensate for neural damage. Pioneering research in this direction was done using the mature technology of silicon microelectronics, but in practice that approach may be a dead end: Both flexible substrates and watery biological environments pose serious problems for silicon devices; in addition, they may be too “noisy” for reliable communication with individual nerve cells.

Of the several material systems being explored as alternatives, graphene – essentially a two-dimensional sheet of carbon atoms linked in a dense honeycomb pattern – seems very well suited to bioelectronic applications: It offers outstanding electronic performance, is chemically stable and biologically inert, can readily be processed on flexible substrates, and should lend itself to large-scale, low-cost fabrication. The latest results from the TUM-Juelich team confirm key performance characteristics and open the way for further advances toward determining the feasibility of graphene-based bioelectronics.

The experimental setup reported in Advanced Materials began with an array of 16 graphene solution-gated field-effect transistors (G-SGFETs) fabricated on copper foil by chemical vapor deposition and standard photolithographic and etching processes. “The sensing mechanism of these devices is rather simple,” says Dr. Jose Antonio Garrido, a member of the Walter Schottky Institute at TUM. “Variations of the electrical and chemical environment in the vicinity of the FET gate region will be converted into a variation of the transistor current.”

Directly on top of this array, the researchers grew a layer of biological cells similar to heart muscle. Not only were the “action potentials” of individual cells detectable above the intrinsic electrical noise of the transistors, but these cellular signals could be recorded with high spatial and temporal resolution. For example, a series of spikes separated by tens of milliseconds moved across the transistor array in just the way action potentials could be expected to propagate across the cell layer. Also, when the cell layer was exposed to a higher concentration of the stress hormone norepinephrine, a corresponding increase in the frequency of spikes was recorded. Separate experiments to determine the inherent noise level of the G-SFETs showed it to be comparable to that of ultralow-noise silicon devices, which as Garrido points out are the result of decades of technological development.

“Much of our ongoing research is focused on further improving the noise performance of graphene devices,” Garrido says, “and on optimizing the transfer of this technology to flexible substrates such as parylene and kapton, both of which are currently used for in vivo implants. We are also working to improve the spatial resolution of our recording devices.” Meanwhile, they are working with scientists at the Paris-based Vision Institute to investigate the biocompatibility of graphene layers in cultures of retinal neuron cells, as well as within a broader European project called NEUROCARE, which aims at developing brain implants based on flexible nanocarbon devices.

This research is supported by the German Research Foundation (DFG) within Priority Program 1459 “Graphene,” the International Helmholtz Research School BioSoft, the Bavarian Graduate School CompInt, the TUM Institute for Advanced Study, and the Nanosystems Initiative Munich (NIM).

Original publication: Graphene Transistor Arrays for Recording Action Potentials from Electrogenic Cells; Lucas H. Hess, Michael Jansen, Vanessa Maybeck, Moritz V. Hauf, Max Seifert, Martin Stutzmann, Ian D. Sharp, Andreas Offenhaeusser, and Jose A. Garrido. Advanced Materials 2011, 23, 5045-5049. DOI: 10.1002/adma.201102990.

Contact:

Dr. J. A. Garrido

Walter Schottky Institute

Technische Universitaet Muenchen

Am Coulombwall 4

85748 Garching, Germany

Tel: +49 89 289 12766

E-mail: garrido@wsi.tum.de

Home page: http://www.wsi.tum.de

Technische Universitaet Muenchen (TUM) is one of Europe's leading universities. It has roughly 460 professors, 9000 academic and non-academic staff, and 31,500 students. It focuses on the engineering sciences, natural sciences, life sciences, medicine, and economic sciences. After winning numerous awards, it was selected as an “Elite University” in 2006 by the Science Council (Wissenschaftsrat) and the German Research Foundation (DFG). The university's global network includes an outpost with a research campus in Singapore. TUM is dedicated to the ideal of a top-level research-based entrepreneurial university.

Media Contact

More Information:

http://www.tum.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…