A Close-up View of Materials as they Stretch or Compress

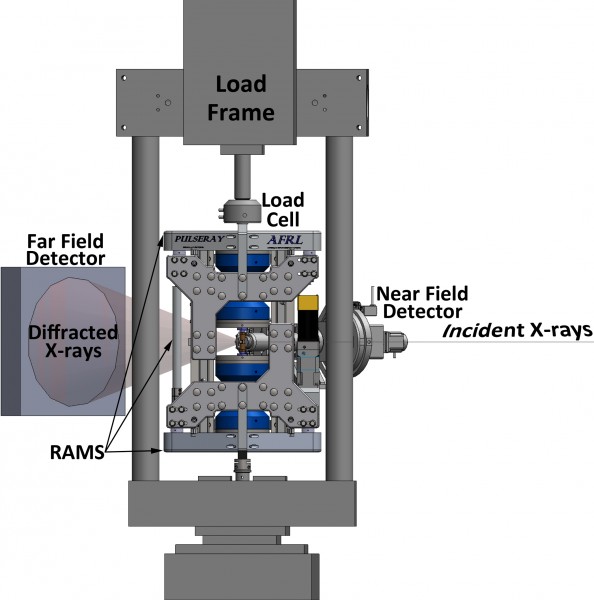

Review of Scientific Instruments This setup is used for high-energy diffraction microscopy experiments—it involves a rotational and axial motion system load frame insert in a conventional load frame along with near-field and far-field detectors. The loading axis is vertical, and the specimen and specimen grips rotate around the loading axis while the rest of the setup remains stationary.

Materials scientists are busy developing advanced materials, while also working to squeeze every bit of performance out of existing materials. This is particularly true in the aerospace industry, where small advantages in weight or extreme temperature tolerance quickly translate into tremendous performance benefits.

The potential pay-offs motivated a team of researchers from the Air Force Research Laboratory, the Advanced Photon Source, Lawrence Livermore National Laboratory, Carnegie Mellon University and PulseRay to work together to pursue their shared goal of characterizing structural materials in unprecedented detail.

In a paper in Review of Scientific Instruments, from AIP Publishing, the group describes how they created a system to squeeze and stretch a material while at the same time rotating and bombarding it with high-energy synchrotron X-rays. The X-rays capture information about how the material responds to the mechanical stress.

“This required developing a loading system to enable the precise rotation of a sample while simultaneously and independently applying tensile or compressive axial loading,” explained Paul A. Shade, lead author and a materials research engineer for the Air Force Research Laboratory at Wright-Patterson Air Force Base.

Their approach included “developing and validating micromechanical models to help us understand the sources of failure in materials so that we can produce aerospace components that are lighter and more damage tolerant — while also gaining a more complete understanding of their service lifetime capability,” Shade added.

The main significance of the team’s new tool is that “the RAMS load frame insert enables applying axial loads while the specimen is continuously rotated, which means that we can integrate near-field and far-field high-energy diffraction microscopy methods and microtomography with in situ mechanical testing,” said Shade. “This allows us to nondestructively characterize the microstructure and micromechanical state of a deforming material—providing critical validation data for microstructure-sensitive performance-prediction models.”

The materials community is interested in using the team's tool as part of an integrated computational materials engineering approach to design structural components — which could help optimize materials properties and reduce uncertainty for given applications. The measurements that this tool enables can be used to develop new materials for turbine engines, car parts and industrial machinery, to name just a few applications.

“An important aspect is to develop trusted materials models whose performance has been validated at the appropriate length scale,” Shade said.

The next step for the team will be partnering with researchers at the Cornell High Energy Synchronous Source (CHESS), Cornell University and the Advanced Photon Source (APS) at Argonne National Laboratory to develop standalone RAMS load frames. “These instruments will be made available to the high-energy synchrotron X-ray community and, in fact, have already been used by many researchers and institutions,” Shade noted.

The team is currently working with CHESS and APS to develop elevated temperature and multi-axial loading capabilities. The RAMS load frame insert has also inspired the development of a tension in-vacuum furnace design for studying irradiated materials at APS that was developed in concert with the Nuclear Engineering Division at Argonne National Laboratory.

“We plan to host the datasets we collect from these experiments for others in the community to use — especially to test new materials models,” Shade said. “In this manner, we’ll help propel the community to develop microstructure-sensitive materials models and provide the validation needed to push materials to the next level of performance.”

The article, “A rotational and axial motion system load frame insert for in situ high- energy x-ray studies,” is authored by Paul A. Shade, Basil Blank, Jay C. Schuren, Todd J. Turner, Peter Kenesei, Kurt Goetze, Robert M. Suter, Joel V. Bernier, Shiu Fai Li, Jonathan Lind, Ulrich Lienert and Jonathan Almer. It appears in the journal Review of Scientific Instruments on September 8, 2015. After that date, it can be accessed at: http://scitation.aip.org/content/aip/journal/rsi/86/9/10.1063/1.4927855

The authors of this paper are affiliated with Air Force Research Laboratory, PulseRay, Argonne National Laboratory, Carnegie Mellon University and Lawrence Livermore National Laboratory.

ABOUT THE JOURNAL

The journal Review of Scientific Instruments, which is produced by AIP Publishing, presents innovation in instrumentation and methods across disciplines. See http://rsi.aip.org

Contact Information

Jason Socrates Bardi

+1 240-535-4954

jbardi@aip.org

@jasonbardi

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…