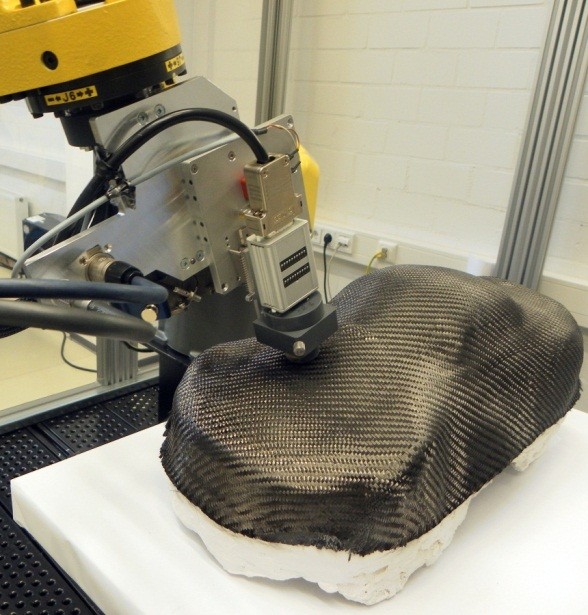

3D eddy current scanner for CFRP

At the JEC Composites Show (Paris, March 11-13, 2014) Fraunhofer IKTS will demonstrate the EddyCUS® system in a joint booth of the Saxony Economic Development Corporation (Hall 7/2, Booth K35).

However, this is valid for defect-free material only. The Fraunhofer Institute for Ceramic Technologies and Systems IKTS develops eddy current based diagnosis systems (EddyCUS®) by which CFRPs can be tested along the process chain, from the raw carbon fiber material to the production of complete assemblies made of CFRP.

By developing a robot based 3D eddy current scanning system, the Fraunhofer Institute for Ceramic Technologies and Systems, branch Materials Diagnostics, accomplished an important step towards production-integrated diagnosis of CFRP. This system combines the following advantages:

Contactless testing of 3D structures

Compared to ultrasonic testing a superior lateral resolution and penetration depth

Rapid adaptation to different testing tasks

Ease of application without radiation protection or coupling media

High velocity up to 500 mm/s

Automatic compensation of unevenness at the testing surface

High defect sensitivity due to multi frequency testing and direction dependent probes

Eddy current based testing methods use the electric properties of carbon fibers for quality evaluation. Because of their ease of application (without coupling media, no radiation protection necessary) they are especially suited for rapid close-to-production testing. Due to its generation of distortion-free conductivity images, the universally parametrizable eddy current scanner EddyCUS® of Fraunhofer IKTS can also be used at 3D structures. The component to be tested is digitalized process-integrated with a stripe-light camera. Based on an automatically calculated path, the robot guides the eddy current sensor orthogonally across the surface. The measuring results are composed to a scanning image (C scan).

A fast adaptation to testing tasks is enabled by a virtually adjusted surface digitalization and surface calculation. Unevenness is compensated nearly completely to keep liftoff effects minimal. Besides high scanning velocity at high resolution, significant properties are preferentially sensor tracing on sloped, planar surfaces and a flexible parametrization of the easily interchangeable sensors. The standard device can capture a maximum surface of 300 x 300 mm at a velocity of 500 mm/s and a sample rate of 3000 S/s. In addition, the EddyCUS® software offers a sequential multi frequency recording of up to four frequencies. Together with direction dependent probes this allows an exact differentiation of defect types.

The Fraunhofer-Gesellschaft is the leading organization for applied research in Europe. Its research activities are conducted by 67 institutes and research units. The Fraunhofer-Gesellschaft employs a staff of more than 23,000, who work with an annual research budget of 2 billion euros. Of this sum, more than 1.7 billion euros is generated through contract research. More than 70 percent of the Fraunhofer-Gesellschaft’s contract research revenue is derived from contracts with industry and from publicly financed research projects. International collaborations ensure direct access to regions of the greatest importance to present and future scientific progress and economic development.

Contact

Jun.-Prof. Dr.-Ing. Henning Heuer

Fraunhofer Institute for Ceramic Technologies and Systems

Branch Materials Diagnostics IKTS-MD

Phone +49 351 88815-630

henning.heuer@ikts-md.fraunhofer.de

Media Contact

More Information:

http://www.ikts-md.fraunhofer.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…

Mobility of the future, quantum technologies, space travel, transfer

The University of Stuttgart at Hannover Messe ’24. From sustainable mobility to quantum technologies and their potential: The University of Stuttgart will be showcasing exciting research projects, pioneering solutions, and…

Culinary pleasure meets innovative cutting-edge research

CeTI Cluster of Excellence at TU Dresden opens “robot kitchen”. April 15, 2024, the Cluster of Excellence Centre for Tactile Internet with Human-in-the-Loop (CeTI) at TUD Dresden University of Technology…