Anti-counterfeiting fluorescent marker developed

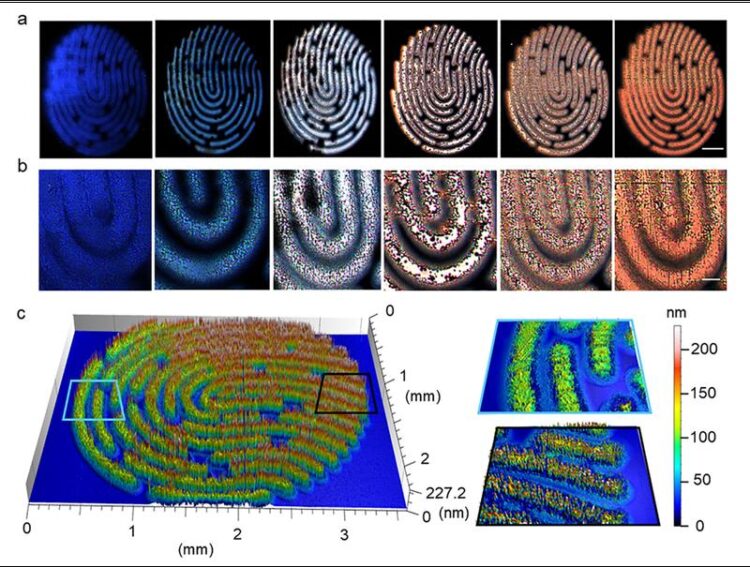

Six different artificial fingerprint patterns with different properties to visualise individual fluorescence and topography. Synthesis parameters were derived from the nanofilm library

(c) Dr Felix Loeffler / Max Planck Institute of Colloids and Interfaces

– Sweet code with laser printing.

A team of researchers at the Max Planck Institute of Colloids and Interfaces (MPICI) has developed a method that could make it more difficult to counterfeit products in the future. The new and patented method makes it possible to produce unique, non-copyable fluorescent patterns quickly, environmentally friendly and at low costs.

Counterfeiting of electronics, certificates or medicines causes billions of dollars in economic losses worldwide every year. The World Health Organisation (WHO) estimates that counterfeit medicines account for 73 billion euros in annual sales. According to the WHO, 50 percent of counterfeit medicines are obtained through unauthorised online mail-order companies. To combat this, medicine packaging will be marked with security features across the EU from 2019. Current counterfeit detection materials, such as those used in fluorescent holograms, typically contain toxic inorganic components. In addition, most of these techniques can be copied within 18 months of decoding the fluorescent compound.

The team led by Dr Felix Löffler from the Department of Biomolecular Systems has come up with a completely new approach to non-copyable nanopatterns in a paper published in the journal Nature Nanotechnology: First, a thin sugar film consisting of simple monosaccharides is bombarded with a laser. In this flash synthesis, the sugar “caramelises” in milliseconds, and at the same time the laser prints random “caramel patterns” on a desired surface. These are unique and fluoresce in different colours under the scanner. Junfang Zhang, first author of the study, says: “The exciting thing here is that you can create any pattern you want, which we have shown using the example of artificial fingerprints. The resulting micro- and nanostructures are completely random. We cannot control them; there will be no pattern”. Dr Felix Löffler adds: “Each sugar pattern has a unique topography, and depending on the laser parameters and additives, we get unique colour gradations of red, green or blue”.

In their experiments, the team created a nanofilm library of about 2,000 nanopatterns. Two scanning methods can be used to quickly and independently read the microstructure of these sugar patterns, which cannot be copied: Fluorescence scanning and topography scanning. Both methods demonstrate almost ideal bit equality, high uniqueness and reliability of the patterns produced. This means that the patterns have a very high degree of randomness, which is important for their function as copy protection. The combination of both methods improves the protection against counterfeiting (PUF = physically unclonable function). “In addition, with our method we can generate up to 10 to the power of 63000 different variants on 1 mm². For comparison, the number of atoms in the universe is about 10 to the power of 89,” says group leader Dr Felix Löffler.

Wissenschaftliche Ansprechpartner:

Dr Felix Löffler – felix.loeffler@mpikg.mpg.de

Originalpublikation:

https://doi.org/10.1038/s41565-023-01405-3

Weitere Informationen:

https://www.mpikg.mpg.de/6802804/news_publication_20429443_transferred?c=132305 (Press release)

https://www.mpikg.mpg.de/SAT (Website of Dr Felix Loeffler)

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…