Making "Frozen Smoke" the Fast Way

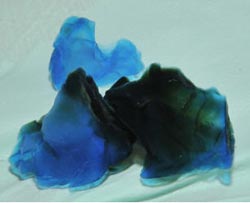

Aerogel samples<br>

One day, Union College’s Aerogel Team’s novel way of making “frozen smoke” could improve some of our favorite machines, including cars.

“When you hold aerogel it feels like nothing – like frozen smoke. It’s about 95 to 97 percent air,” said Ann Anderson, professor of mechanical engineering. “Nano-porous, solid and very low density, aerogel is made by removing solvents from a wet-gel. It’s used for many purposes, like thermal insulation (on the Mars Rover), in windows or in extreme-weather clothing and sensors.”

Together with Brad Bruno, associate professor of mechanical engineering, Mary Carroll, professor of chemistry and others, Anderson is studying the feasibility of commercializing their aerogel fabrication process. A time and money-saver, it could appeal to industries already using aerogel made in other ways.

During rapid supercritical extraction (RSCE), chemicals gel together (like Jell-O) in a hot press; the resulting wet-gel is dried by removing solvents (the wet part). The remaining aerogel (dried gel), is created in hours, rather than the days or weeks alternative methods take.

RSCE, Anderson said, is also approximately seven times cheaper, requiring one hour of labor for every 8 hours the other methods need.

A good place for such a process, and Union aerogel, is the automotive industry.

“Our 3-way catalytic aerogels promote chemical reactions that convert the three major pollutants in automotive exhaust – unburned hydrocarbons, nitrogen oxides and carbon monoxide – into less harmful water, nitrogen and carbon dioxide,” Anderson said. “Because aerogels have very high surface areas and good thermal properties, we think they could replace precious metals, like platinum, used in current catalytic converters.”

Indeed, the surface area of one 0.5-gram bit of aerogel equals 250 square meters.

“That’s a lot of surface area for gases to come in contact with, facilitating very efficient pollution mitigation,” Anderson said.

The team’s work has received support from the National Science Foundation, the ACS Petroleum Research Fund and the Union College Faculty Research Fund.

Media Contact

More Information:

http://www.union.eduAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…